Drum Gear Couplings

As a key component in modern industrial transmission systems, drum gear couplings play an irreplaceable role in the field of heavy machinery. Compared with traditional spur gear couplings, this coupling device with a special drum shaped tooth design has significantly improved load-bearing capacity, compensation performance, and durability.

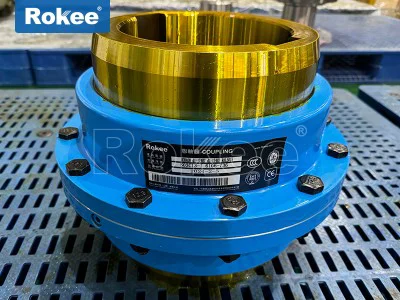

Drum gear coupling belongs to rigid flexible coupling, and its core structure consists of two main parts: inner gear ring and flange half coupling with outer teeth. The unique feature of this coupling lies in its external tooth design - the external teeth are made into a spherical shape, with the center of the sphere located on the gear axis, forming the so-called "drum shaped teeth". Compared with ordinary spur gear couplings, the tooth clearance of drum gear couplings is significantly increased, and this special design endows it with a series of excellent performance.

The geometric features of drum shaped teeth are very unique. In the longitudinal direction of the tooth, the tooth thickness gradually decreases from the center to both ends, forming a drum shaped curve as a whole. This type of curve is usually composed of single or multiple arcs, and the radius of the bulge circle directly affects the compensation ability and tooth contact state of the coupling. A well-designed drum shaped curve needs to meet two basic requirements: first, there should be no edge contact phenomenon at the maximum axial inclination angle; The second is to minimize the concentrated load on the gear teeth as much as possible, which requires the radius of the bulge circle to be as large as possible.

From the perspective of material selection, high-quality drum gear couplings are usually made of high-quality alloy steels such as 42CrMo, 20CrMnTi, etc. After undergoing precise carburizing and quenching processes, these materials can achieve a tooth surface hardness of HRC58-62 and a wear-resistant layer depth of 1.2-1.8mm, far exceeding the industry average. The combination of this material and process ensures the long-term reliable operation of the coupling under heavy load conditions.

In terms of working principle, the drum gear coupling transmits torque and rotational motion through the meshing of inner and outer teeth. When there is relative displacement between the two axes, the special design of the drum shaped teeth allows the inner and outer tooth surfaces to slide relative to each other within a certain range, thereby compensating for the axis deviation. Specifically, it can handle three basic types of displacement simultaneously: axial displacement (offset along the axis direction), radial displacement (parallel offset between axes), and angular displacement (angle between axes). This multi-directional compensation capability makes it an ideal choice for complex operating conditions.

It is worth mentioning that drum gear couplings have special lubrication requirements. Due to the periodic axial relative sliding between the inner and outer tooth surfaces during operation, good lubrication is crucial for reducing wear and power loss. According to different application scenarios, grease lubrication or forced thin oil lubrication systems can be used. The latter can significantly reduce tooth surface wear, with wear only about 10% of grease lubrication, while also taking away the heat generated by friction to prevent material performance degradation.

Drum gear couplings are highly favored in the industrial transmission field, mainly due to their excellent technical performance. Compared with traditional spur gear couplings, it has a series of obvious advantages, which directly translate into the reliability and economy of equipment operation.

The significant improvement in load-bearing capacity is one of the most notable features of drum toothed couplings. Under the same outer diameter size conditions, the torque transmission capacity of the drum toothed coupling is on average 15% to 20% higher than that of the straight toothed coupling. This improvement is due to the optimization of the tooth surface contact conditions in the design of the drum shaped teeth, which makes the load distribution more uniform.

The enhancement of displacement compensation capability is another major advantage. When the radial displacement is zero, the allowable angular displacement of a spur gear coupling is usually only 1 °, while a drum gear coupling can reach 1 ° 30 ', with an increase of 50%. This enhanced compensation capability effectively reduces the requirements for installation accuracy, while also minimizing additional loads caused by misalignment of the axis. In practical applications, drum gear couplings can handle angular deviations of up to 6 °, but it is generally recommended to use them within a range of 1.5 ° to 2.5 ° for optimal lifespan.

In terms of transmission efficiency, the drum gear coupling also performs well, with a theoretical transmission efficiency of up to 99.7%. This high efficiency is due to optimized tooth profile design that reduces friction losses, while precise manufacturing processes ensure meshing accuracy. High efficiency not only means less energy waste, but also less heat generation, which helps to extend the life of the coupling.

The drum gear coupling has also significantly improved in terms of service life and maintenance cycle. The drum shaped tooth surface avoids stress concentration caused by the edge compression of the tooth end under angular displacement conditions in straight tooth couplings, while improving the friction condition of the tooth surface. With appropriate lubrication system, the maintenance cycle can be extended to three times that of a spur gear coupling. Models that use forced thin oil lubrication can even achieve 10000 hours of maintenance free operation, significantly reducing downtime.

In addition, the drum gear coupling also has the advantage of compact structure. Compared to other coupling types with similar compensation capabilities, its radial size is smaller and the turning radius is smaller, which is particularly valuable in space limited applications. The horn shaped design of the outer gear sleeve teeth also makes installation and disassembly more convenient, reducing maintenance time consumption.

The comprehensive manifestation of these technological advantages makes the drum gear coupling the preferred solution for coupling selection under heavy load, high precision, or complex working conditions. With the continuous advancement of manufacturing technology and the improvement of design theory, the performance of drum gear couplings continues to improve, providing a more reliable transmission solution for modern industrial equipment.

After years of development, drum gear couplings have formed a series of standardized and specialized product types to meet the needs of different industrial scenarios. Understanding these types and their characteristics is crucial for proper selection and application.

The standard model series forms the foundation of drum gear coupling products. According to Chinese machinery industry standards such as JB/T 8854, drum gear couplings are mainly divided into multiple series such as GICL, GIICL, GCLD, etc. Among them, GIICL type is further divided into Type I and Type II: Type I adopts a separated sealing end, allowing for larger radial displacement and adapting to Y, J1, and Z1 axial extensions; Type II is an integral sealed end with a more compact structure, suitable for Y and J1 type shaft extensions. These standard models have a wide range of nominal torque, ranging from 0.4kN · m to 4500kN · m, with shaft hole diameters covering 16mm to 1040mm, and a maximum allowable speed of 4000r/min, which can meet most conventional application requirements.

Special function models are variant products developed for specific working conditions. The WGP type drum shaped toothed coupling with brake disc integrates braking function, saving installation space; The WGC type is designed specifically for vertical installation, solving the special requirements of vertical equipment transmission; The WGZ model comes with brake wheels, making it easy to integrate with the braking system; The WGJ and WGT models are equipped with intermediate sleeves or shafts, which are used in situations where the connection distance needs to be extended. These special models greatly expand the application range of drum gear couplings, enabling them to adapt to various complex mechanical layouts and functional requirements.

Industry specific models reflect the customized development of drum gear couplings in different fields. For example, the TGL type uses nylon inner gear rings, which have better cushioning and vibration reduction performance; NGCL type is designed specifically for applications with brake wheels and complies with JB/ZQ4644 standards; The NL type also uses nylon internal gear rings and is manufactured according to the DB 3202-87 standard. These specialized models have been optimized for specific industry operating conditions, such as hygiene requirements in the food and beverage industry and frequent start stop of logistics equipment, providing more professional solutions.

From the perspective of size specifications, the selection range of drum gear couplings is extremely wide. There are 28 basic specifications and 20 structural types of drum gear couplings commonly found in the market, with a maximum aperture of 1200mm and a maximum torque bearing capacity of approximately 8.19 million Newton meters. This wide parameter range ensures that almost any equipment with power and speed requirements can find a matching coupling model. Taking the GIICL series as an example, there are 20 specific models ranging from GII-CL1 to GII-CL20, and users can make precise selections based on parameters such as torque, speed, and shaft diameter.