Safety Couplings

A safety coupling is a specially designed mechanical transmission component that can automatically cut off power transmission in the event of overload, stalling, or other abnormal working conditions in the transmission system, protecting mechanical equipment from damage. Compared with traditional couplings, safety couplings not only have the function of transmitting torque, but also have overload protection characteristics, making them an indispensable safety component in modern industrial automation systems.

The core working principle of the safety coupling is based on a mechanical overload protection mechanism. When the torque of the transmission system exceeds the preset safety value, the coupling will achieve protection through the following methods:

Friction disengagement: Friction plates that use preset friction force slip during overload

Shear type disconnection: Design weak links (such as shear pins) break when overloaded

Magnetic separation: automatically separated by electromagnetic force or permanent magnets when overloaded

The key technical parameters include:

Rated torque: transmission capacity under normal working conditions

Detachment torque: critical value for triggering protective action

Reset method: manual reset or automatic reset

Response time: the time from overload to complete disengagement

Main types and structural characteristics

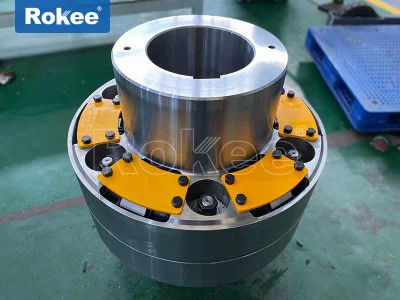

Friction type safety coupling

Adopting a multi plate friction structure, torque transmission is controlled by spring preload force. When overloaded, the friction plate slips and has the advantage of being reusable, widely used in fields such as machine tools and packaging machinery.Shear pin safety coupling

Built in precise calculation of shear pins, which can break and cut off power transmission when overloaded. Simple structure and low cost, but requires replacement of shear pins to restore use, commonly found in agricultural machinery and conveying equipment.Magnetic safety coupling

Using permanent magnets or electromagnetic force coupling to transmit torque, the magnetic coupling automatically disengages when overloaded. It has the characteristics of non-contact and wear free, suitable for clean environments and high-precision equipment.Hydraulic safety coupling

By controlling torque transmission through hydraulic pressure, the disengagement torque can be precisely adjusted, and it is commonly used in large industrial equipment and heavy-duty situations.

Application field

Automated production line: protecting robot joints and conveyor belt drive devices

Machine tool industry: prevent spindle overload damage and protect precision machining equipment

Packaging machinery: Avoid mechanical damage during processes such as film stretching and sealing

Wind power industry: protecting gearboxes from extreme wind conditions

Elevator system: as a safety device to prevent overloading operation

Proper installation is a prerequisite for ensuring the reliable operation of a safety coupling:

Accuracy requirements for alignment (usually radial deviation<0.1mm, angular deviation<0.5 °)

Pre tightening force control of fastening bolts (using torque wrench)

Lubrication requirements (choose appropriate lubricant according to type)

Daily maintenance should include:

Regularly check the condition of the coupling

Monitoring working temperature (abnormal temperature rise may indicate problems)

Check if the fasteners are loose

Record overload events and their handling status

As the "safety valve" of mechanical transmission systems, the correct selection and use of safety couplings directly affect the safety and reliability of equipment. With the development of industry, safety couplings are evolving from simple mechanical components to intelligent safety components, providing more reliable protection for modern industrial production.