Motor Couplings

Motor coupling is a key component in mechanical transmission systems, used to connect the motor shaft with the driven equipment shaft and achieve power transmission. This mechanical device can not only transmit rotational motion and torque, but also compensate for misalignment between the two axes to varying degrees, protecting the equipment from the effects of vibration and impact.

Motor couplings play multiple important roles in mechanical systems:

Power transmission: Efficiently transmitting the rotational power generated by the motor to the driven equipment is the most basic function of the coupling.

Inter axis compensation:

Radial misalignment compensation: allows for a certain offset between the two axis centerlines

Angle misalignment compensation: Tolerant for angle deviation between two axes

Axial displacement compensation: adapted to the relative movement of the shaft in the length directionVibration damping: Absorbs and reduces vibrations and impacts generated by motors or loads, protecting the transmission system.

Overload protection: Some couplings are designed to disconnect in case of overload, preventing equipment damage.

The working principle of a coupling is based on mechanical connection and elastic deformation. When the motor rotates, torque is transmitted from the active part of the coupling to the driven part, and power transmission may be achieved through gear meshing, deformation of elastic elements, or friction. High performance couplings can effectively compensate for various misalignment situations without affecting transmission efficiency.

Main types and characteristics of motor couplings

Rigid coupling

Sleeve coupling: The simplest form of coupling, consisting of an integrated sleeve and fasteners. The installation accuracy requirement is extremely high, with no compensation capability, suitable for high-precision positioning systems.

Flange coupling: rigidly connected by flanges and bolts, capable of transmitting high torque, mainly used for large heavy-duty equipment such as ship propulsion systems.

Clamp shell coupling: The shaft end is clamped by two half shells, which is easy to disassemble and assemble but has poor balance. It is commonly used for vertical shaft connections.Elastic coupling:

Rubber component type: using the elastic deformation of rubber to compensate for deviations, with excellent vibration reduction performance, suitable for occasions with vibration isolation requirements

Metal spring type: using coil spring or spiral spring, with long service life and high temperature resistance, used for high-precision servo systems

Polyurethane type: with good comprehensive performance, wear-resistant and oil resistant, widely used in packaging machinery

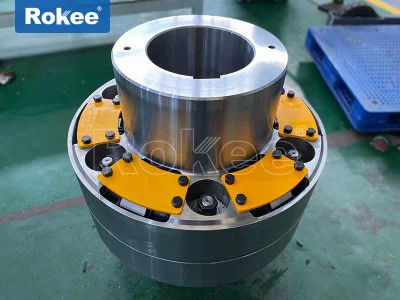

Gear coupling: transmits torque through the meshing of internal and external gears, allowing for large radial and angular deviations, with high lubrication requirements, commonly found in metallurgical equipment.

Diaphragm coupling: Flexible connection achieved by metal diaphragm group, zero backlash, maintenance free, especially suitable for high-speed turbine machinery.

Universal joint: Adopting a cross axis or ball cage structure, it can achieve large angle transmission and is widely used in vehicle transmission systems.

Chain coupling: With a simple structure and low cost, but high noise and low precision, it is commonly used in non precision applications such as agricultural machinery.Special function coupling

Safety coupling: It automatically disengages when the torque exceeds the set value, protecting valuable equipment from damage. There are various types such as friction type and steel ball type.

Magnetic coupling: It achieves non-contact transmission through permanent magnets, completely sealed without leakage, and is an ideal choice for chemical pumps.

Hydraulic coupling: Utilizing liquid viscosity to transmit torque, it can achieve stepless speed regulation and is used for large construction machinery.

Key performance parameters of motor couplings

Torque capacity: including rated torque, peak torque, and alternating torque bearing capacity, is the primary basis for selection.

Speed range: Couplings have a maximum allowable speed limit, and special attention should be paid to the dynamic balance level for high-speed applications.

Compensation ability for misalignment:

Radial deviation: usually 0.1-5mm

Angle deviation: generally 0.5 ° -3 °

Axial displacement: mostly between ± 1- ± 10mmStiffness characteristics: torsional stiffness affects the response speed of the system, and radial stiffness does not compensate for the misalignment of the relationship.

Inertia moment: For high dynamic response systems, low inertia couplings can significantly improve positioning accuracy.

Environmental adaptability: including special requirements such as temperature range, corrosion resistance, and explosion-proof rating.

Selection considerations

Power parameters: motor power, speed, starting characteristics

Shaft conditions: shaft diameter, shaft spacing, alignment accuracy

Load characteristics: constant load, impact load, periodically changing load

Environmental factors: temperature, humidity, corrosiveness, explosion-proof requirements

Space limitations: installation space size, ease of disassembly and maintenance

Cost factor: Balance between initial purchase cost and long-term maintenance expenses

Recommended Common Application Scenarios

Servo system: Priority should be given to zero backlash diaphragm couplings or bellows couplings

Pump equipment: Elastic couplings or toothed couplings can effectively absorb vibrations

Compressor: High speed applications should use diaphragm couplings that have undergone precision dynamic balancing

Lifting machinery: gear couplings or safety couplings that require high torque capacity

Food and medicine: hygienic couplings or non lubricated magnetic couplings to avoid contamination

Selection steps

Determine the shaft diameter and installation space

Calculate the required transmission torque (considering starting torque and load factor)

Assess the misalignment of the shaft system

Choose the appropriate type of coupling

Check the limiting conditions such as speed and temperature

Consider special environmental requirements

Verify the convenience of installation and disassembly

With the advancement of industry and intelligent manufacturing, couplings are transforming from simple mechanical components to intelligent system components, and their reliability and functionality will continue to improve, providing more comprehensive transmission solutions for modern industrial equipment.