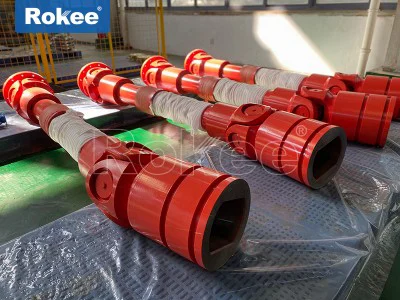

Universal Couplings

Universal coupling is a mechanical device that achieves non collinear transmission of two axes through a special mechanism, and can stably transmit torque and motion at an axis angle of 5 °-45 °. Its core function is to dynamically compensate for angle deviation, while also serving as a buffer for vibration reduction and improving the dynamic performance of the shaft system.

As a key component in mechanical transmission systems, universal couplings play an irreplaceable role in modern industrial equipment. It can solve the problem of power transmission when the axis is not centered or there is an angle, and is widely used in various fields from heavy machinery to precision equipment.

Universal joint is a mechanical component used to connect two shafts (active shaft and passive shaft) in different mechanisms. Its core function is to enable the two shafts to achieve continuous rotation and reliably transmit torque and motion without being on the same axis and with an axis angle. This unique performance makes it an indispensable component of mechanical transmission systems, especially suitable for situations where axial displacement is inevitable due to design, installation, or operation.

From the perspective of structural characteristics, the most significant advantage of universal couplings is their large angular compensation capability. The allowable angle between the two axes of universal couplings with different structural forms is generally between 5 ° -45 °, which provides great flexibility for mechanical design. Meanwhile, universal couplings usually have the characteristics of compact structure and high transmission efficiency, which can achieve efficient power transmission in limited space. In high-speed and heavy-duty power transmission, certain types of universal couplings also have the functions of buffering, damping, and improving the dynamic performance of the shaft system, which is crucial for protecting mechanical equipment and extending its service life.

The basic components of a universal joint include two universal joint forks and a cross shaft assembly (taking the cross shaft type as an example). The joint is composed of two halves, which are respectively connected to the driving shaft and the driven shaft. Generally, most power machines are connected to the working machine through couplings. This structure enables the coupling to operate normally with a certain offset between the shafts, without the need for precise alignment, greatly reducing the difficulty of installation and debugging.

From the perspective of material selection, universal couplings are usually made of high-strength materials such as 45 steel, 45 forged steel, 40 chromium or cast iron to ensure sufficient strength and durability. After appropriate heat treatment processes, these materials can meet the mechanical performance requirements under different working conditions. For special environments such as corrosive media or high temperature conditions, stainless steel or other special alloy materials may also be used.

The universal joint in modern industrial applications has developed into various structural forms, including cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type. These different types of universal couplings have their own characteristics and are suitable for different application scenarios and working conditions.

In practical applications, universal couplings can be divided into four specifications based on the magnitude of the transmitted torque: heavy, medium, light, and small. Heavy duty universal couplings are mainly used in heavy industries such as metallurgy and mining, and can transmit extremely high torque; Small universal couplings are commonly used in precision instruments, small machinery, and other applications, emphasizing precision and flexibility rather than torque capacity.

The reason why universal couplings can transmit power in the presence of an angle between their axes is due to their unique kinematic principles and intricate mechanical structure. A deep understanding of its working principle is crucial for the correct selection, use, and maintenance of universal couplings. The core function of a universal joint is to solve the problem of axis misalignment, which may include three basic situations: axial displacement (two axis lines parallel but not on the same straight line), radial displacement (two axis lines intersecting but not on the same straight line), and angular displacement (two axis lines at a certain angle). Universal couplings can effectively compensate for these displacements, ensuring the continuity and stability of power transmission.

The cross axis universal joint, as the most typical type, consists of two universal joint forks and a cross axis in its basic structure. The four ends of the cross shaft are connected to two fork heads through needle roller bearings, which allows the two connected shafts to produce relative angular displacement in multiple directions. When the driving shaft rotates, the driven shaft is driven to rotate by the cross shaft, and torque can be transmitted even when there is an angle between the two shafts. However, the single cross axis universal joint has an inherent characteristic: when there is an angle between the two shafts, the angular velocity of the driven shaft will periodically change, resulting in speed fluctuations and additional dynamic loads. The magnitude of this fluctuation is proportional to the angle between the two axes, and when the angle is 30 °, the velocity fluctuation can reach about 30%. To solve this problem, a dual universal joint arrangement is commonly used in practical applications, which eliminates velocity fluctuations and achieves constant speed transmission through specific spatial geometric relationships (such as placing the fork heads at both ends of the intermediate shaft in the same plane and making the angle between the intermediate shaft and the main and driven shafts equal).

The ball cage universal joint adopts a completely different constant velocity principle. Its core structure consists of an inner ball cage, an outer ball cage, a retaining frame, and a force transmitting steel ball. Through precise spherical geometric relationships, the force transmitting steel ball is always located on the bisector of the angle between the two axes, thus achieving true constant speed transmission. The advantages of the ball cage universal joint are smooth transmission, high efficiency, a large allowable working angle (up to 45 °), and high speed capability. Therefore, it is widely used in automotive drive shafts and other applications. Another common type of constant velocity universal joint is the ball fork universal joint, which has a relatively simple structure but strong load-bearing capacity and is commonly used in heavy-duty vehicles.

From a dynamic perspective, the universal joint not only transmits the main torque during operation, but also generates additional bending moments and axial forces due to the angle between the axes. These additional loads increase rapidly with the increase of the angle, so in practical applications, the axis angle should be minimized as much as possible, generally not exceeding 15 ° -20 °. For situations that require large angle transmission, a specially designed universal joint should be selected, and special support structures should be considered to withstand these additional loads.

The lubrication system of the universal joint is also a core part of its design. Good lubrication can significantly reduce wear and prolong service life. Modern universal couplings often use lithium based grease centralized lubrication systems. For high temperatures or special environments, synthetic grease or special lubricants need to be selected. Some high-performance universal couplings are also equipped with sealing systems to prevent lubricant leakage and contamination from entering, which is particularly important in harsh working conditions such as mining and metallurgy.

The cross axis universal joint is the most traditional and common type, with a relatively simple structure consisting of two fork shaped joints and a cross axis. The angle change is achieved through needle roller bearings on the cross axis. This type of coupling has the characteristics of high load-bearing capacity, reliable structure, and easy maintenance, making it particularly suitable for heavy machinery. According to the different designs of the bearing seat and cross head, the cross shaft universal joint can be divided into various forms: SWC type integral cross head universal joint (JB/T 5513-2006), SWP type partial bearing seat cross shaft universal joint (JB/T 3241-2005), SWZ type integral bearing seat cross shaft universal joint (JB/T 3242-1993), etc. Among them, the SWP type split bearing seat cross axis universal joint is made of forged steel material and follows the JB3241-91 standard. Its rotation diameter covers 160-640mm, and the nominal torque range is 16-1250kN · m. It achieves displacement compensation in all directions through the split bearing seat structure, and the axis angle can reach 10 ° (5 ° for G type). It is mainly used for the transmission shaft connection of heavy equipment such as steel rolling machinery and lifting and transportation machinery.