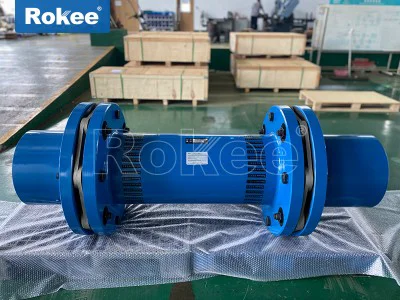

Membrane Couplings

As a core component in modern mechanical transmission systems, membrane couplings have been widely used in the industrial field due to their unique structure and excellent performance. This metal elastic element flexible coupling achieves power transmission and deviation compensation through a precision designed stainless steel diaphragm group, perfectly solving various challenges faced by traditional couplings in complex working conditions.

Membrane coupling is a high-performance flexible coupling that uses metal elastic elements, representing the advanced level of modern coupling technology. Compared with traditional couplings, membrane couplings demonstrate significant advantages in the field of mechanical transmission through their unique working principle and structural design. The core lies in utilizing the elastic deformation ability of the membrane group composed of multiple layers of stainless steel thin plates to compensate for various misalignment situations between connected shafts, while efficiently transmitting torque.

In terms of basic structure, the membrane coupling mainly consists of three parts: two shaft sleeves (or half couplings) installed on the driving shaft and the driven shaft respectively, and a diaphragm group connecting these two shaft sleeves. The membrane group is usually composed of multiple ultra-thin high-strength stainless steel circular thin plates stacked together, which are precision machined with bolt holes and special stress relief grooves. According to different design requirements, the diaphragm can be divided into two basic forms: linkage type and integral type. The connecting rod diaphragm is connected to the inner and outer rings through multiple separate connecting rod arms, while the whole piece adopts a continuous integral ring structure. Both have their own characteristics in stiffness and compensation ability.

The working principle of membrane couplings is based on the theory of metal elastic deformation. When the driving shaft rotates, torque is transmitted to the diaphragm group through bolt connections. The diaphragm undergoes slight elastic deformation when subjected to torque, thereby transmitting the rotational motion to the driven shaft. During this process, if there are axial, radial, or angular deviations between the two axes, the diaphragm can absorb these deviations through its flexible deformation, avoiding stress concentration and equipment damage that may occur due to rigid connections. It is worth noting that the deformation of the membrane is inversely proportional to its thickness, so it is necessary to accurately calculate the membrane thickness during design to achieve the ideal balance between stiffness and compensation capability.

The torque transmission mechanism of the membrane coupling is very efficient. During operation, torque is converted into shear stress inside the diaphragm. Due to the high strength and fatigue durability of stainless steel material, stable transmission performance can be maintained even under high load conditions. Compared with traditional forms such as gear couplings or chain couplings, membrane couplings do not have components that slide relative to each other, so they do not require lubrication and avoid wear and efficiency degradation caused by poor lubrication.

The environmental adaptability of membrane couplings is extremely outstanding. Its working temperature range can span extreme conditions from -80 ℃ to+300 ℃, and some special designs can even work stably in cryogenic environments of -196 ℃ or high temperature environments of+500 ℃. In addition, due to the fact that metal materials themselves are not affected by oil, moisture, and most chemical media, membrane couplings can operate reliably for a long time in harsh industrial environments that are humid, dusty, or have corrosive gases. This is an advantage that many couplings that require rubber or plastic components cannot match.

Membrane couplings play an important role in the industrial transmission field, mainly due to their unique and excellent performance characteristics. These characteristics not only solve the inherent defects of traditional couplings, but also provide reliable guarantees for the efficient and stable operation of modern mechanical equipment. A deep understanding of these core advantages can help engineers make more rational choices when designing transmission systems.

Excellent deviation compensation capability is one of the most striking features of membrane couplings. In actual mechanical installation, a completely ideal alignment state is almost non-existent, and there will always be some axial, radial, or angular deviations. The membrane coupling, with its elastic diaphragm design, can effectively compensate for these installation deviations. The data shows that the angular deviation compensation capability of the membrane coupling can reach 1.5 degrees, which is twice that of the traditional gear coupling; The radial deviation compensation amount is usually 0.2-0.6mm, and the axial floating range can reach ± 0.5mm. This powerful compensation capability significantly reduces the demanding requirements for equipment installation accuracy, reduces installation and debugging time and costs. It is worth mentioning that the coupling compensation performance of the dual membrane structure is more outstanding, as it allows the two sets of membranes to bend in different directions, thus better adapting to complex deviation situations.

The seamless transmission characteristics make membrane couplings outstanding in the field of precision transmission. Unlike gear couplings or slider couplings with backlash, membrane couplings achieve zero rotational clearance power transmission through rigid connections between metals. This feature is crucial for high-precision applications such as servo systems and CNC machine tools, as it can effectively avoid positioning errors caused by reverse clearance. At the same time, the seamless design also eliminates the impact noise generated by traditional couplings during reversing, making the equipment run more smoothly and quietly. Tests have shown that the torsional stiffness of high-quality membrane couplings can reach over 3400N · m/rad, which can meet the rigidity requirements of the vast majority of high-precision transmission systems.

From a maintenance perspective, the maintenance free design of membrane couplings brings significant operational advantages. Traditional gear couplings require regular replacement of lubricating oil and seals, while membrane couplings do not require lubrication at all, eliminating the need for lubrication systems and related maintenance work. This not only reduces long-term maintenance costs, but also avoids the risk of failure caused by poor lubrication. In industries with high cleanliness requirements such as food and medicine, non lubricated design can also prevent oil contamination of products. The mean time between failures (MTBF) of membrane couplings usually exceeds 50000 hours, and some can even reach over 100000 hours, truly achieving reliable operation of "installation is forgotten".

Membrane couplings perform equally well in vibration damping and noise control. The multi-layer stainless steel diaphragm assembly constitutes an efficient vibration damping system, which can effectively absorb torsional vibrations and impact loads generated by equipment such as engines and compressors. Test data shows that the membrane coupling can reduce the vibration amplitude of the transmission system by 30% -50%, which is extremely beneficial for protecting precision bearings and extending equipment life. At the same time, due to the absence of relatively sliding components, the noise level of membrane couplings during operation is usually below 70 decibels, much lower than the 85-90 decibels of gear couplings, improving the quality of the working environment.

Environmental adaptability constitutes another major advantage of membrane couplings. Its temperature resistance range is extremely wide, and standard products can work stably in environments ranging from -80 ℃ to+300 ℃. Specially designed models can even adapt to more extreme temperature conditions. membrane couplings also have good corrosion resistance and can resist corrosion from various chemical media such as acid, alkali, salt spray, etc. In harsh working conditions with high humidity and dust, such as mining, metallurgy, chemical and other industries, membrane couplings exhibit a longer service life than rubber component couplings. According to practical application statistics, under the same working conditions, the service life of membrane couplings is generally 3-5 times that of elastic couplings.

Lightweight and compact design are common pursuits in modern mechanical equipment, and membrane couplings also have significant advantages in this regard. Compared to gear couplings that transmit the same torque, membrane couplings can reduce their volume by 20% -30% and weight by 15% -25%. Taking a coupling that transmits a torque of 1000N · m as an example, the weight of a toothed coupling is about 12kg, while a membrane coupling with the same performance weighs only about 9kg. This compact and lightweight design reduces bearing load and saves installation space, making it particularly suitable for weight and space sensitive fields such as aviation and ships.

The high power density characteristics of membrane couplings meet the needs of modern mechanical development towards high power and high speed. With the advancement of materials science and manufacturing technology, the torque transmission capacity of modern membrane couplings has been greatly improved, with a maximum of 8.1 million N · m and a speed of tens of thousands of revolutions per minute. This powerful power transmission capability enables membrane couplings to be successfully applied in heavy-duty fields such as generator sets and ship propulsion systems. At the same time, the membrane coupling can maintain a constant dynamic balance accuracy, and even during high-speed operation, it will not produce significant vibration due to centrifugal force, ensuring the smooth operation of the transmission system.

After years of technological development and practical application, membrane couplings have evolved into various structural forms, each with its unique design characteristics and applicable scenarios. Understanding these different types of membrane couplings and their structural differences is crucial for selecting and optimizing the transmission system design correctly. According to the number of membrane groups, connection methods, and specific structural characteristics, membrane couplings can be divided into several main categories.

Single diaphragm and double membrane couplings are the most basic classification methods. The structure of a single membrane coupling is relatively simple, consisting of a set of diaphragms connected to two shaft sleeves, and has the advantages of low cost, light weight, and high torsional stiffness. However, its ability to compensate for axis deviation is relatively limited, mainly suitable for situations with high accuracy or small deviation. In contrast, the double membrane coupling adopts a structure of two sets of diaphragms and one intermediate section, forming a more flexible three-stage structure. This design enables the coupling to compensate for more complex deviation situations through the different deformations of two sets of membranes, making it particularly suitable for long wheelbase transmission or installation environments with poor alignment conditions. Actual application data shows that the angular compensation capability of the double membrane coupling can be improved by 40% -60% compared to the single diaphragm type, making it the preferred choice for most heavy-duty and high-speed applications.

From the perspective of connection methods, membrane couplings can be divided into two series: flange type and clamping type. The flange type membrane coupling is connected by bolt flanges and has the characteristics of high torque transmission, good rigidity, and reliable connection. It is commonly used in high-power transmission systems such as steam turbines, compressors, and pump sets. The clamping membrane coupling is directly fixed to the shaft end using the clamping force generated by high-strength bolts, eliminating the need for flange structure and making the overall structure more compact and lightweight. It is widely used in precision transmission applications such as servo motors and stepper motors. The expansion sleeve connection type membrane coupling that has emerged in recent years combines the advantages of both, achieving high-precision positioning and large torque transmission through keyless expansion sleeves, and is particularly suitable for working conditions with high requirements for shaft hole fit or frequent disassembly.

According to specific structural characteristics and applications, membrane couplings have also developed various specialized models. JMI type membrane coupling is a typical single diaphragm structure, which adopts an integral diaphragm design and has a simple and reliable structure; The JMIJ type features a dual membrane structure with an intermediate sleeve, enhancing its ability to compensate for deviations; The JMII series has further strengthened its structure and is suitable for heavy machinery and high torque applications. SJM double membrane couplings are designed for harsh environments such as chemical pumps and aviation power systems, and have excellent corrosion and high temperature resistance performance; The JZM type membrane coupling for heavy machinery has been optimized for extreme load conditions in the mining and metallurgical industries, with a rated torque of over 40kN · m and the ability to withstand strong impacts and vibrations.

The stepped membrane coupling represents a special design concept, where the diaphragm groups are arranged in a stepped manner. This structure not only increases torsional stiffness but also enhances the axial floating ability of the coupling. Another advantage of stepped design is that it disperses stress concentration and extends the fatigue life of the diaphragm, making it particularly suitable for applications with large axial displacement or frequent start stop, such as ship propulsion systems, reciprocating compressors, etc. Tests have shown that the axial compensation capability of the stepped membrane coupling can be improved by 30% -50% compared to conventional designs, while the lifespan of the diaphragm is extended by about 20%.

The shape and arrangement of the diaphragm of the membrane coupling are also different, forming different performance characteristics. Common membrane shapes include circular, hexagonal, octagonal, and cross shaped. Circular membrane is easy to manufacture and has a lower cost; Polygonal membranes (such as hexagonal or octagonal) can provide more uniform stress distribution and higher torque density; The membrane with a special curved contour optimizes the elastic deformation characteristics and achieves better deviation compensation effect. There are two basic forms of membrane arrangement: parallel stacking and staggered stacking. Parallel stacking has higher stiffness, while staggered stacking has better flexibility. Engineers can choose according to specific needs.

Micro membrane couplings constitute another important type, such as the ZMJM type, which can have an outer diameter as small as about 10mm and are designed specifically for precision instruments, small servo systems, and medical equipment. Although the micro membrane coupling has a small size, it still maintains the basic characteristics of metal membrane couplings, including no backlash, high stiffness, and precise transmission. In situations where high transmission accuracy is required for robot joints, optical platforms, and precision measuring equipment, micro membrane couplings demonstrate irreplaceable value. It is worth noting that micro membrane couplings have more stringent requirements for manufacturing accuracy, typically requiring micrometer level machining tolerances and special dynamic balancing treatments.