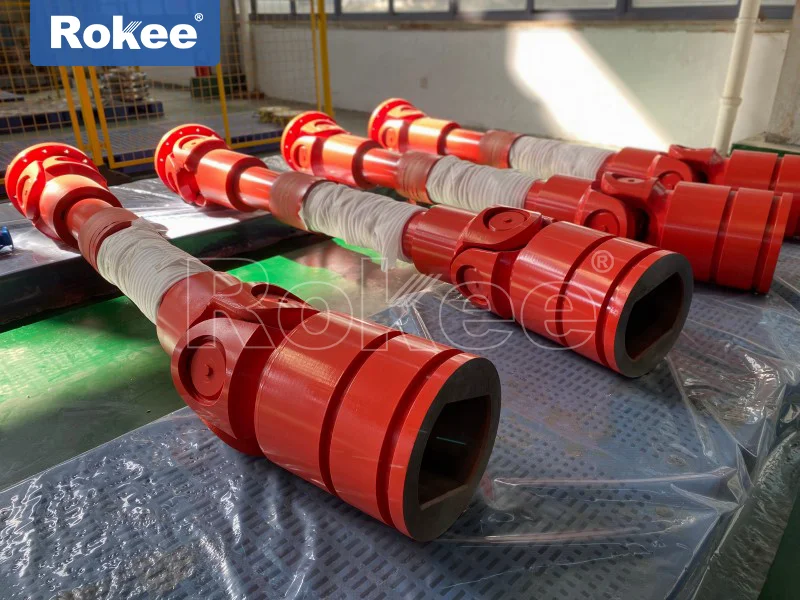

Scalable Cardan Shafts

Scalable cardan shaft is a highly engineered mechanical transmission component that integrates the functions of cardan shafts and telescopic mechanisms. It can achieve reliable transmission of power and motion in the presence of angular deviation and axial displacement between shaft systems. The emergence of such devices greatly expands the possibilities of mechanical design and solves complex working conditions that traditional rigid connections cannot cope with.

The expandable cardan shaft mainly consists of three core parts: the cardan shaft mechanism, the telescopic mechanism, and the connecting components. The cardan shaft mechanism usually adopts a cross axis or ball cage design, which is a key part to achieve angle compensation. The cross axis type consists of two fork shaped joints and a cross axis, allowing for significant angular deviation between the two axes; The cage type is composed of inner and outer cages and steel balls, which can adapt to more complex transmission angle changes and provide higher transmission efficiency and stability. The telescopic mechanism often adopts a spline pair design, which compensates for the axial displacement between connected devices by the axial sliding of the inner shaft inside the outer shaft. The connecting components may include various forms such as flanges, sleeves, keyways, etc., depending on specific application requirements, to ensure reliable connection with the driving and driven ends.

The working principle of a scalable cardan shaft is based on two basic mechanisms: angle compensation and axial displacement compensation. When there is an angle deviation between the driving shaft and the driven shaft, the cardan shaft mechanism ensures that power transmission is not affected through its hinge characteristics. The cross axis cardan shaft adapts to angle changes through the rotation of the cross axis, while the cage type achieves the same goal through the rolling of steel balls in the inner and outer raceways. When there is axial displacement between the two shafts, the telescopic mechanism comes into play, and the spline pair allows the length of the shaft to freely change within a certain range, while ensuring effective torque transmission. This dual compensation mechanism enables the telescopic cardan shaft to adapt to various complex installation and operating conditions.

From the perspective of material selection, stretchable cardan shafts are usually made of high-strength alloy steels such as 35CrMo or 20CrMnTi, which have undergone quenching and high-frequency quenching processes and have excellent wear resistance and fatigue strength. The bearing part is designed with needle roller bearings or sliding bearings according to the speed and load requirements. Good lubrication can significantly extend the service life of cardan shafts, so most products are equipped with dedicated oil fittings to ensure that the lubricant can reach all critical friction areas.

It is worth noting that the design of modern telescopic cardan shafts is increasingly emphasizing modularity and standardization. The series of products represented by SWC-CH type, SWP-F type, etc. have formed a complete size and parameter system, making it convenient for users to choose the appropriate model according to specific needs. This standardization trend not only reduces manufacturing costs, but also improves product reliability and interchangeability, making expandable universal shafts widely used in various industrial fields.

-

Classification Of Universal Joint Couplings

-

Model Of Cross Axis Universal Shaft Coupling

-

Working Principle Of Cardan Shaft Coupling

-

Structure Of Universal Shaft Coupling

-

Function Of Universal Joint Coupling

-

Types Of Universal Joint Couplings

-

Specification And Model Of Universal Joint Coupling

-

Composition Of Universal Joint Coupling