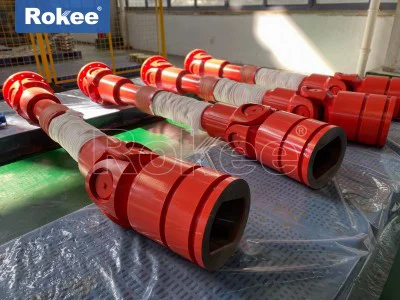

SWP Universal Shafts

SWP universal shaft as a core component in the field of heavy machinery transmission, plays an irreplaceable role in industrial fields such as metallurgy, lifting, and mining due to its angular compensation capability and high torque transmission characteristics. SWP type split bearing seat cross axis universal shaft is a heavy-duty transmission device made of forged steel material. The original design intention is to solve the problem of efficient power transmission in the case of misalignment of the central axis of heavy-duty equipment, while reducing maintenance difficulty and downtime.

The SWP universal shaft adopts a split bearing seat structure, where the bearing seat cover is divided into two parts and fixed by bolt connection. When the bearing needs to be replaced due to wear, simply loosen the bolt to disassemble the bearing seat, without the need to move the entire equipment or disassemble adjacent components. This design reduces bearing replacement time by over 70% and significantly lowers maintenance costs. In contrast, integral bearing seat couplings require complete disassembly of the coupling during bearing replacement, resulting in significantly prolonged equipment downtime.

The cross shaft, as the core transmission component, is made of high-strength alloy steel and undergoes carburizing and quenching treatment, while the core maintains good toughness. The four necks of the cross shaft are equipped with needle roller bearings, which consist of a cage, needle rollers, and sealing rings and can withstand extremely high radial loads. During operation, the cross axis compensates for the angular deviation between the two axes through its own rotational motion.

The SWP universal shaft adopts a built-in lubrication channel design, which delivers lubricating grease to each friction pair through oil channels distributed on the bearing seat and cross shaft. Standard models are equipped with oil injection nozzles and oil discharge ports, supporting non-stop lubrication.

Flange connection method: Multiple flange configurations are provided according to different models: Type A uses short flanges with a compact structure; E-type configuration with brake wheel flange, suitable for situations requiring rapid braking; The F-type is a large telescopic flange with an axial compensation of up to 150mm. The flange connection surface is finely ground with a flatness error of no more than 0.02mm, ensuring uniform torque transmission and reducing bolt load.

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling

-

Roller Universal Shafts

-

Types Of Universal Shaft Couplings