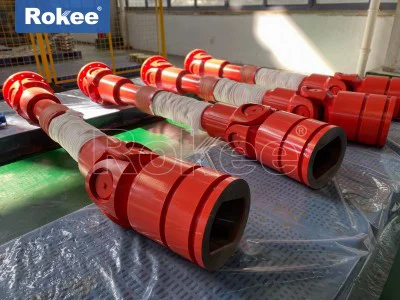

Cardan Shaft Of Rolling Machine

As the core transmission component of metal sheet forming equipment, the universal shaft of the rolling machine directly affects the rolling accuracy and equipment reliability.

The cardan shaft of the rolling machine adopts a heavy-duty transmission design:

Cross axis component: forged from 42CrMo alloy steel, with a surface carburizing and quenching hardness of HRC58-62, and ultra precision grinding of the bearing position

Expansion spline: modulus 8-12mm, hardness HRC50-55, axial compensation ± 50-100mm

Flange connection: standard flange interface, pre tightened with 8.8 grade high-strength bolts

Balance system: hydraulic counterweight device, balance torque error ≤ 3%

Power transmission characteristics of cardan shaft in plate rolling machine

Transmitting the torque of the main motor to the work roll through a cross axis articulated structure

Axial displacement caused by compensating roller gap adjustment of spline pair

Drum shaped tooth surface design increases the contact area by 40% and reduces contact stress by 35%

Advantages of universal shaft in plate rolling machine

Heavy load capacity: Special alloy material increases torque density by 25%

Precision compensation: Drum shaped tooth design allows for compensation of 1.5 ° angular deviation

Intelligent monitoring: optional vibration and temperature sensors (accuracy ± 0.5%)

Easy maintenance: Split bearing design reduces replacement time by 60%

-

Scalable Cardan Shafts

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling

-

Roller Universal Shafts

-

Types Of Universal Shaft Couplings

-

Function Of Cross Cardan Shaft