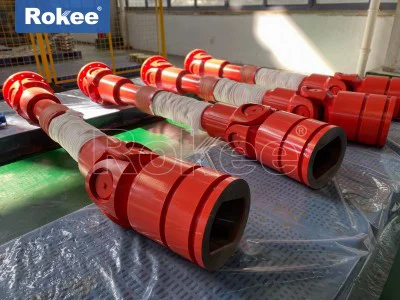

Universal Shaft of Rolling Mill

As the core component of the transmission system in the metallurgical industry, the cardan shaft of the rolling mill plays a crucial role in transmitting the torque of the main motor to the rolling mill.

The cardan shaft of the rolling mill adopts a modular composite structure design:

Cross axis component: forged from 42CrMo alloy steel, with a surface carburizing and quenching hardness of HRC58-62. The bearing position adopts ultra precision grinding technology (Ra ≤ 0.2 μ m)

Fork head component: Made of integral forged 20CrMnTi material, with a fatigue life of over 10 ⁷ cycles, equipped with heavy-duty four row tapered roller bearings

Expansion spline: module 6-12mm, hardness HRC50-55, axial compensation ± 50-150mm

Balance system: Hydraulic cylinder counterweight design, balance torque error ≤ 3%

Power transmission characteristics of universal shaft coupling in rolling mill

Torque transmission is achieved through the articulated structure of the cross axis and fork head, allowing for an inclination angle of up to 3 ° (conventional design 1.5 °)

Axial displacement caused by spline compensation roller adjustment

The specially designed drum shaped tooth surface increases the contact area by 40% compared to traditional straight teeth, and reduces contact stress by 35%

Advantages of rolling mill universal shaft:

Heavy load capacity: The special alloy steel material increases torque density by 25%, which is 15-20% higher than conventional products.

Convenient maintenance: The split bearing design reduces the replacement time from 48 hours to 12 hours

Intelligent monitoring: Integrated vibration and temperature sensors, real-time monitoring of cross axis wear status

Environmental adaptation: High temperature resistant design

-

Long Telescopic Cardan Shaft Coupling

-

Welded Universal Joint Coupling

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling