Material Of Universal Joint Coupling

As a key component in mechanical transmission, the material selection of universal joint couplings directly affects their performance, service life, and applicable scenarios. According to current industrial application requirements, mainstream materials can be divided into the following categories:

Stainless steel material

304 stainless steel

Features: strong corrosion resistance, suitable for humid, acid-base environment (such as food processing, marine equipment). Application: Micro precision couplings, medical equipment transmission components. Advantages: High surface smoothness, no need for additional coating treatment, low maintenance cost. Representative products: WSD series cross universal joint, expandable stainless steel coupling.Upgraded performance of 316 stainless steel: more resistant to chloride ion corrosion than 304, suitable for marine or chemical environments. Typical scenarios: offshore platform drive shaft, seawater desalination equipment.

Alloy steel material

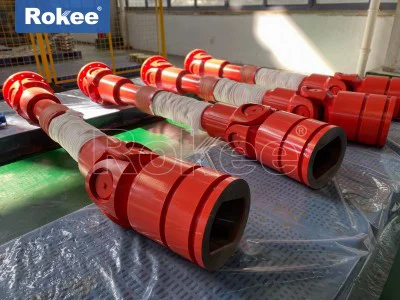

40Cr/42CrMo

Heat treatment process: After quenching and tempering, the hardness reaches HRC28-32, which combines toughness and wear resistance. Applicable fields: heavy machinery (mining equipment, rolling mills), high torque transmission. Case: SWC heavy-duty universal joint, commonly used in the metallurgical industry.45 # steel

Economic choice: Low cost, surface hardness improved after quenching treatment, suitable for small and medium-sized agricultural machinery transmission shafts. Limitations: Poor corrosion resistance, requiring regular oil coating for rust prevention.

Aluminum alloy material

Lightweight design: With a density only one-third that of steel, it is suitable for high-speed and low load scenarios. Typical applications: drone power transmission, automated assembly line.

Special composite materials

Advantages of carbon fiber reinforced polymer: It is extremely lightweight and has strong fatigue resistance, and is used in aerospace or high-end racing transmission systems. Challenge: High cost and difficult processing.

Nylon coated metal for shock absorption and noise reduction: The inner layer is made of steel core and the outer layer is coated with nylon, suitable for precision instruments.