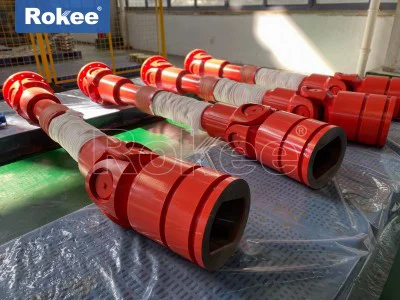

SWC Universal Joint Couplings

SWC universal joint coupling is a key component in mechanical transmission systems, widely used in various industrial equipment.

The SWC universal joint coupling belongs to the cross axis universal joint, and its core structure consists of the following parts:

Flange fork head: adopting an integral bolt free design, usually in the form of welding or flange connection, providing structural strength and reliability;

Cross shaft: As the core component of the coupling, it realizes angle changes and torque transmission;

Bearing components: generally using needle roller bearings to reduce friction and improve transmission efficiency;

Sealing device: prevents dust and impurities from entering the interior of the bearing, extending its service life;

Spline expansion part (some models): allows axial displacement compensation.

The working principle of SWC universal joint coupling is based on the hinge characteristics of the cross shaft, which can achieve constant or approximately constant speed power transmission in the presence of an angle between the two shafts. When the driving shaft rotates, the motion is transmitted to the driven shaft through the hinge action of the cross shaft, even if the centerlines of the two shafts are not on the same straight line.

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling

-

Roller Universal Shafts

-

Types Of Universal Shaft Couplings