Material Of Universal Shaft Coupling

The material selection of universal shaft coupling directly affects its load-bearing capacity, wear resistance, and service life.

Classification of Core Component Materials

Cross axis component

Mainstream materials: 42CrMo alloy steel (commonly used), 40Cr, 20CrMnTi, etc. After tempering or carburizing heat treatment, these materials have both high strength and wear resistance.

Process characteristics: Forging processes such as free forging or die forging are usually used to eliminate casting defects and improve material density.Fork/flange components

Common materials: 45 steel, 35CrMo, cast iron (for light load scenarios).

Manufacturing process: The plug part is mostly cast, while the fork head for heavy-duty applications is made of forged steel to improve fatigue resistance.Bearing components

Needle roller bearings: commonly used high carbon steel or carburized bearing steel, suitable for high-speed and high load working conditions.

Sliding bearings: available in bronze alloy or self-lubricating composite materials for maintenance free environments.

Special application material optimization

Corrosion resistant environment: using stainless steel (such as 304/316) or surface nickel/zinc plating treatment, commonly found in ships and chemical equipment.

Lightweight requirements: Some small couplings use aluminum or titanium alloys, but some strength needs to be sacrificed.

High temperature scenario: For metallurgical equipment, choose 35CrMo or 42CrMo and add high-temperature resistant coatings.

The material of the universal shaft coupling should be selected comprehensively based on load, speed, environment, etc. For heavy-duty applications, alloy steel such as 42CrMo should be preferred, while for economical scenarios, 45 steel can be considered. Special working conditions require targeted optimization of material and process combinations.

-

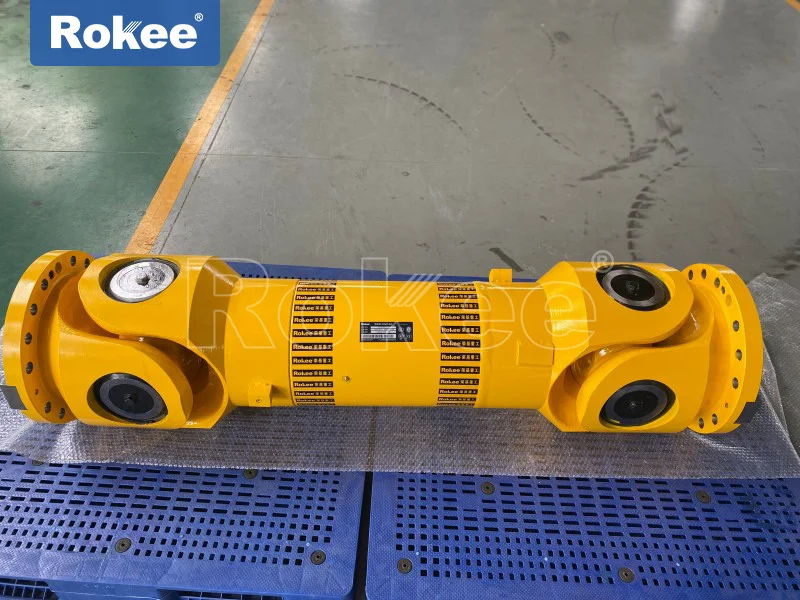

Internal Structure Of Cross Axis Universal Shaft Coupling

-

Internal Spline Universal Joint Coupling

-

Scalable Universal Joint Couplings

-

Universal Joint Coupling Manufacturer In China

-

Material Of Universal Joint Coupling

-

Telescopic Universal Shaft Coupling

-

Purpose Of Universal Joint Coupling

-

Flange Cardan Shaft