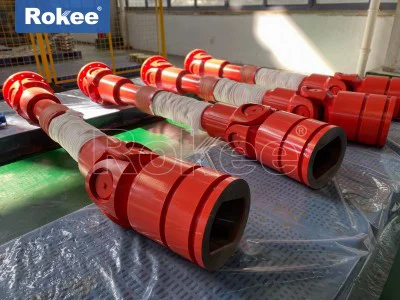

Telescopic Universal Shaft Coupling

As an important mechanical transmission component, the telescopic universal shaft coupling plays an indispensable role in modern industrial equipment. It has dual functions of axial expansion compensation and angle deflection compensation, which can effectively solve the problem of axis misalignment caused by installation errors, thermal expansion and contraction, or foundation settlement in the transmission system.

The telescopic universal shaft coupling is a mechanical transmission device that can simultaneously compensate for axial displacement and angular deviation. It solves the application limitations of traditional couplings in complex working conditions through a unique structural design. This type of coupling usually consists of two parts: a universal shaft coupling and a telescopic spline. The universal shaft coupling is responsible for angle compensation, while the telescopic spline structure adjusts axial displacement. In practical applications, when the transmission shaft system is misaligned due to installation errors, thermal deformation during equipment operation, or foundation settlement, the telescopic universal shaft coupling can automatically adjust to ensure the continuity and stability of power transmission, while effectively reducing additional loads and vibrations caused by misalignment.

Compared with traditional rigid couplings, telescopic universal couplings have significant technical advantages. Firstly, it allows for significant installation deviations between the two connecting shafts, reducing the precision requirements for equipment installation and minimizing installation adjustment time and costs. Secondly, during the operation of the equipment, it can automatically compensate for changes in axis position caused by thermal expansion, bearing wear, or foundation deformation, protecting bearings and transmission components from damage caused by additional loads. In addition, the reasonable selection of telescopic universal couplings can effectively isolate vibration and impact, improve the reliability and service life of the entire transmission system.

In terms of industrial applications, telescopic universal couplings almost cover all fields that require flexible transmission. From heavy metallurgical machinery to precision packaging equipment, from high-speed rotating generators to low-speed high torque construction machinery, its presence can be seen. Especially in applications such as rolling mills, ship propulsion systems, oil drilling equipment, and large fans that require high reliability and adaptability, the telescopic universal shaft coupling plays an irreplaceable role. With the development of modern industrial equipment towards high speed, heavy load, and precision, as well as the increasing requirements for equipment maintenance convenience and energy efficiency, the technology and market of telescopic universal couplings are still continuously developing and innovating.

The brilliance of the telescopic universal shaft coupling lies in its unique mechanical structure design, which combines the angular compensation function of the universal shaft coupling with the axial expansion and contraction ability of the spline shaft, creating a transmission solution that adapts to complex working conditions. A typical telescopic universal shaft coupling mainly consists of core components such as a cross shaft assembly, universal shaft coupling fork, telescopic spline pair, and lubrication and sealing system. The cross shaft assembly, as a key component for angle compensation, is usually forged from high-strength alloy steel. The four shaft necks undergo precision grinding and surface hardening treatment to ensure excellent wear resistance even under high loads. The universal shaft coupling fork connects the cross shaft and the transmission shaft, and its design needs to balance strength and lightweight requirements. Common structural forms include integral forging and split assembly, with the former having good rigidity and the latter being easy to maintain and replace.

According to different structural forms and application requirements, various types of telescopic universal couplings have been developed, each with its unique performance characteristics and applicable scenarios. Understanding the differences between these types is crucial for proper selection and optimization of transmission system design. Divided from the main structure, common types of telescopic universal couplings include cross shaft type, ball cage type, and ball fork type. They each have their own strengths in load-bearing capacity, speed range, angle compensation performance, and manufacturing accuracy.

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling

-

Telescopic Cardan Shafts

-

Welded Cardan Shaft