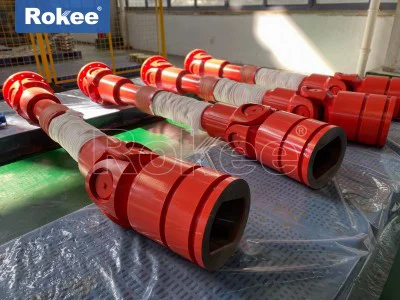

High Speed Cardan Shaft Coupling

High speed cardan shaft coupling is a key component in industrial transmission systems, which can achieve large angle, non concentric shaft power transmission under high-speed operating conditions. Adopting precision dynamic balancing technology to ensure low vibration even under conditions of thousands of revolutions per minute. The material balances wear resistance and fatigue resistance. Needle roller bearings or ball cage structures reduce friction losses and increase the upper limit of rotational speed. Supports multiple interfaces such as expansion splines and flanges, suitable for high-speed scenarios such as machine tool spindles and wind turbine gearboxes.

Maintenance and optimization

Regular lubrication: Use high-temperature grease (such as lithium based grease) and replenish it every 500 hours.

Installation calibration: Ensure that the angle between the two axes is ≤ 15 ° to avoid additional bending moments during high-speed operation.