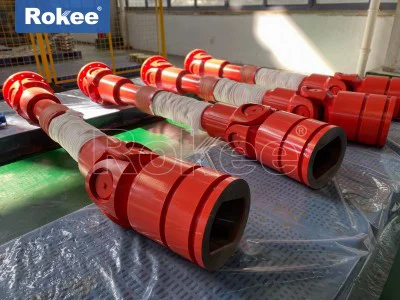

Model of Cross Cardan Shaft

Cross cardan shaft is a mechanical device widely used in industrial transmission systems, mainly for transmitting torque and rotational motion, especially suitable for conditions where there is an angle between two axes or non coaxial working conditions. According to different structures, uses, and performance requirements, there are various models and series of cross universal couplings.

SWC series cross cardan shaft

Features: Adopting an integral fork head bolt free connection structure, it has high reliability, long service life, and high transmission efficiency. Suitable for industries such as metallurgy, lifting, engineering transportation, mining, petroleum, and shipbuilding.

Typical models: SWC100, SWC120, SWC150, SWC180, SWC200, SWC250, SWC315, SWC350, etc.

SWP series cross cardan shaft

Features: Adopting a split bearing seat design, it is easy to disassemble and maintain quickly, suitable for heavy equipment such as steel rolling machinery, lifting and transportation machinery, etc.

Typical models: SWP160, SWP180, SWP200, SWP225, SWP250, SWP315, etc.

WS series (small cross cardan shaft)

Features: Suitable for small transmission systems, compact structure, and a small range of nominal torque transmission (11.2~1120N · m).

Typical models: WS1, WSD1, WS2, WSD2, etc., divided into single type (WSD) and double type (WS).

Application: Suitable for transmission shaft systems with two axis angles ≤ 45 °.

WSN series (universal joint coupling for orthodontic machines)

Features: Designed specifically for roll type sheet metal straightening machines, with an axis angle of ≤ 10 ° and a rotation diameter of 46-150mm.

Typical models: WSL1, WSL2, WSL3, WSL4, etc.

WSH series (sliding bearing structure)

Features: Adopting sliding bearings and cross axis structure, suitable for various industrial scenarios, with multiple models (standard expansion welding type, long expansion welding type, etc.).

SWP-F type (large telescopic single type)

Features: It has a large expansion and contraction capacity (up to 150mm), suitable for heavy load conditions such as metallurgy, lifting, and mining.

-

Scalable Cardan Shafts

-

Cardan Shaft Of Rolling Machine

-

Transmission Principle Of Universal Joint Coupling

-

Applicable Occasions For Cross Axis Universal Coupling

-

Advantages And Disadvantages Of Universal Joint Couplings

-

Internal Spline Universal Shaft Coupling

-

Telescopic Cardan Shafts

-

Welded Cardan Shaft