Flexible diaphragm coupling is a kind of high-performance flexible coupling, which compensates axial and angular displacements by the deformation of elastic diaphragm while transferring torque, metal membrane coupling features with compact structure, large transmission torque, long service life, maintenance-free, high temperature resistance, acid and alkali resistance, and corrosion resistance, suitable for shafting transmission in high temperature, high speed and corrosive environment.

China National Flexible Membrane Couplings

-

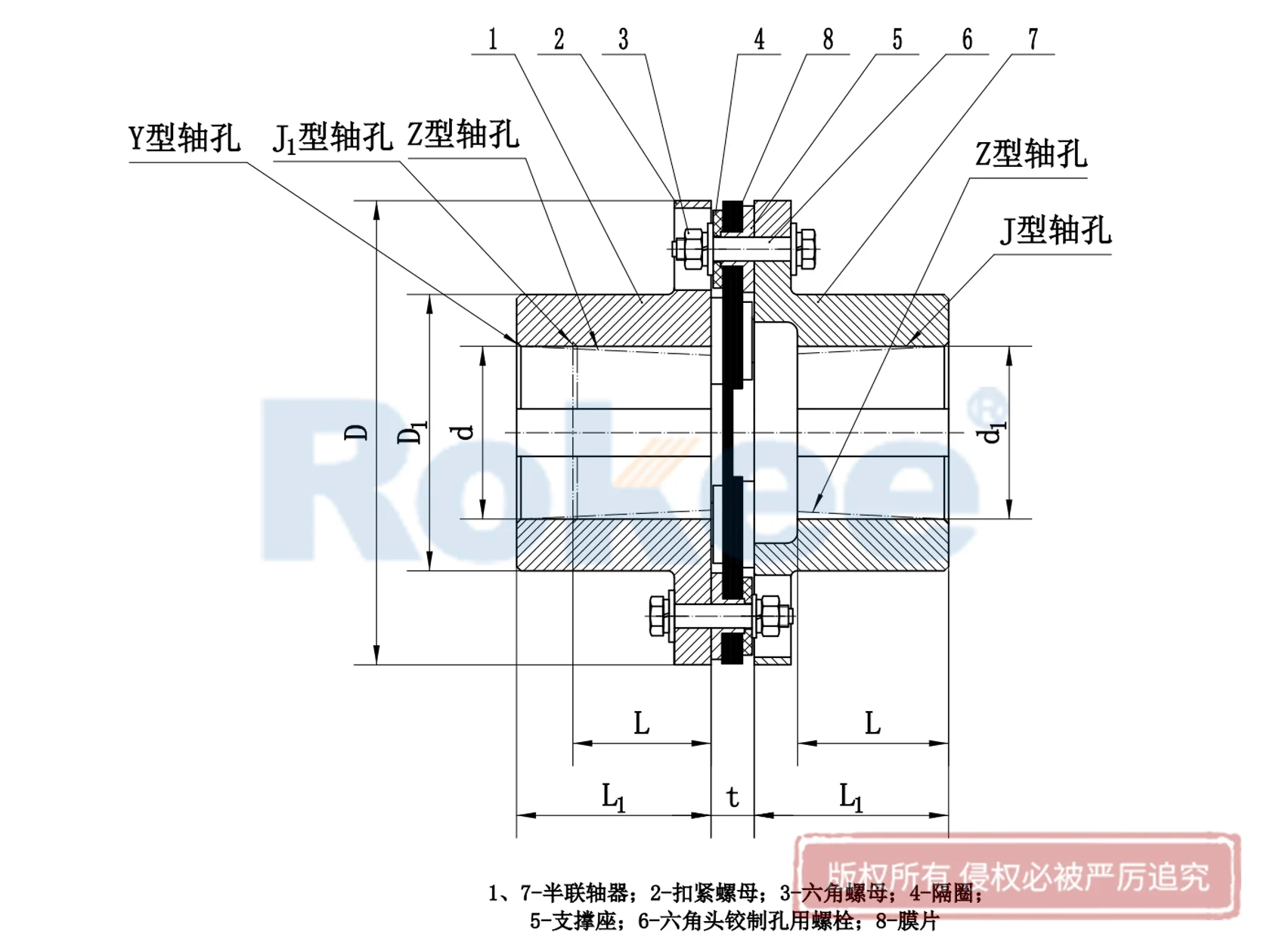

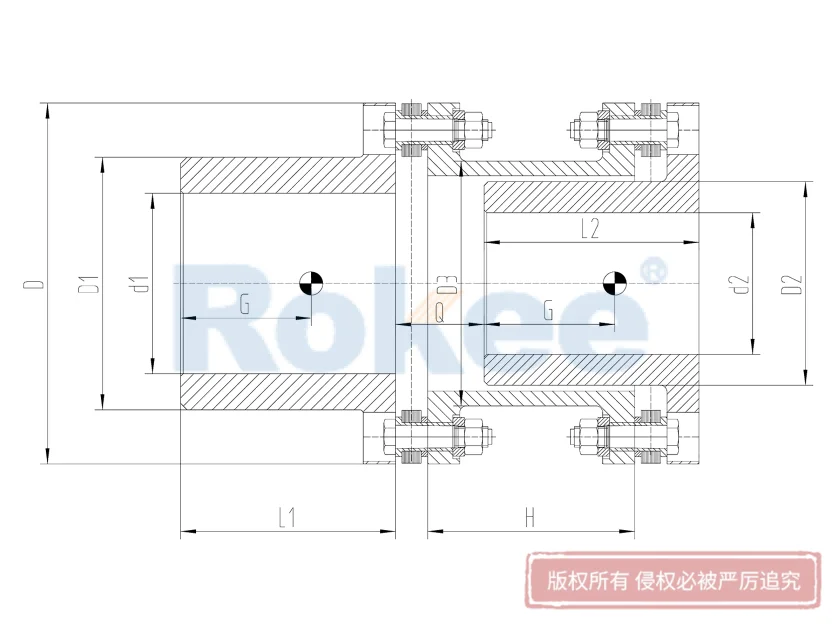

JMI Single Diaphragm Coupling

JMI Single Diaphragm Coupling -

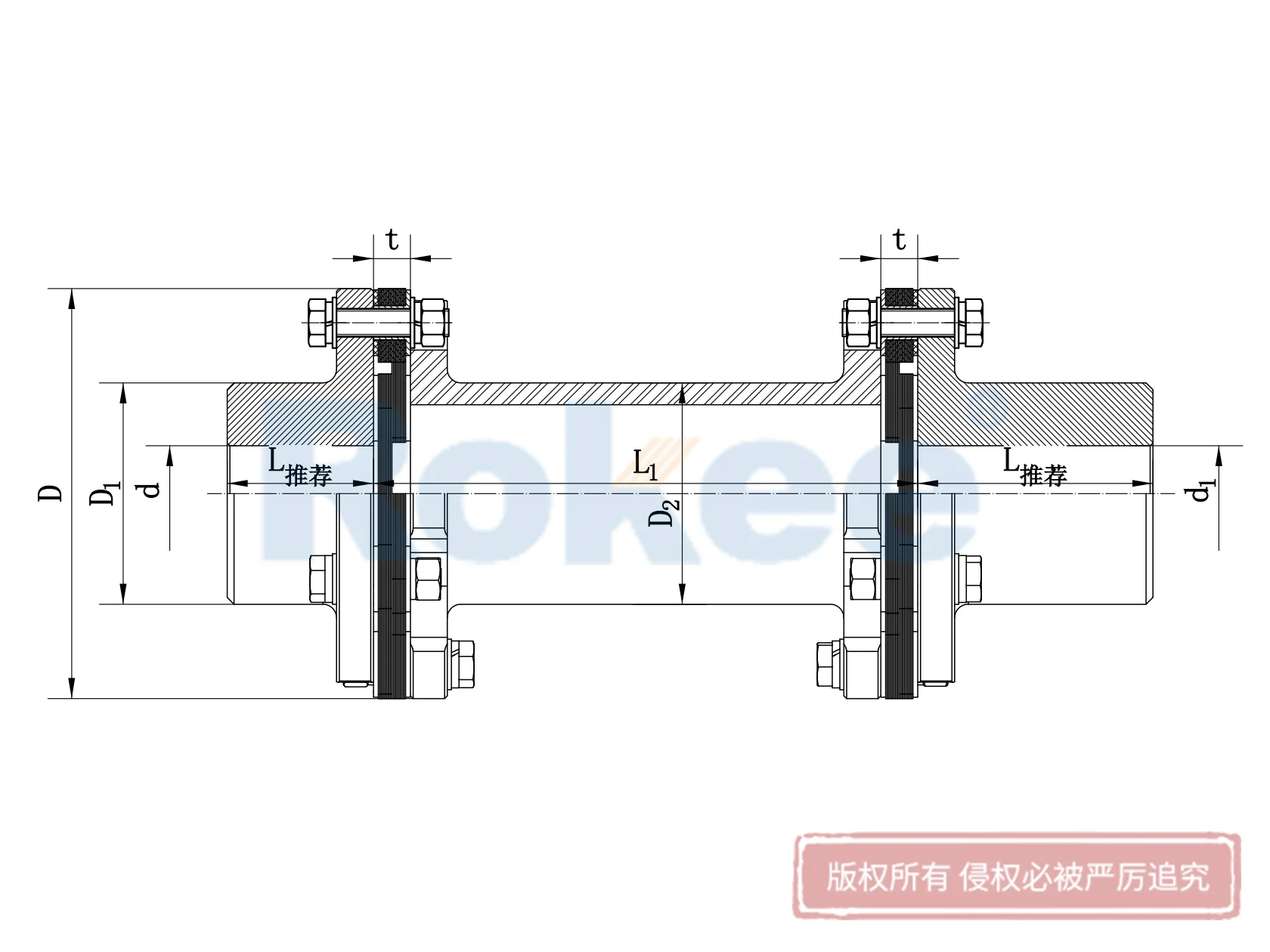

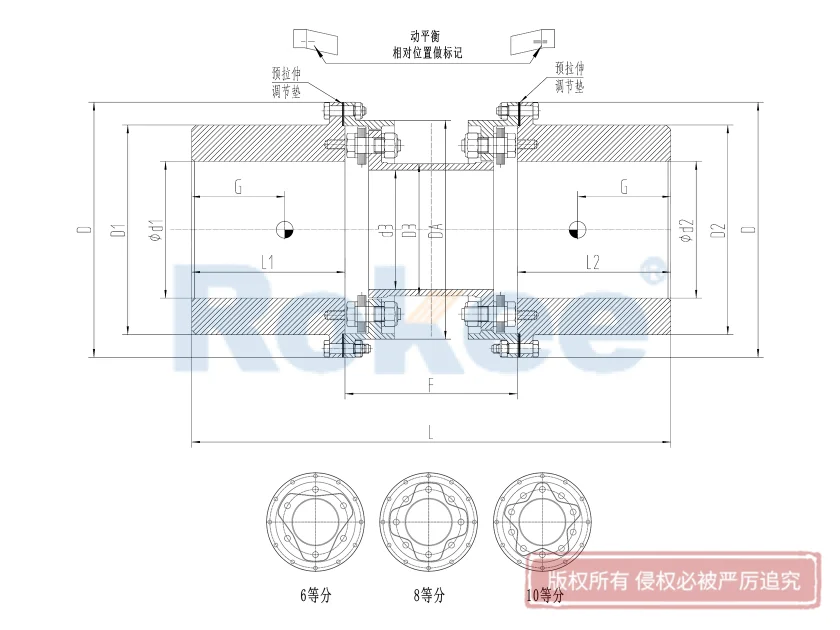

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ Double Diaphragm Coupling With Intermediate Shaft -

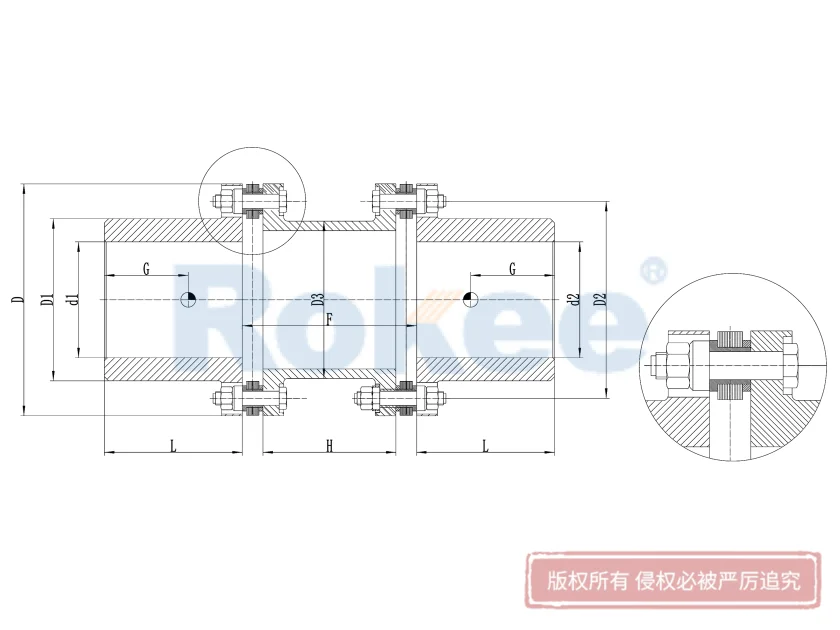

JMII Single Diaphragm Coupling

JMII Single Diaphragm Coupling -

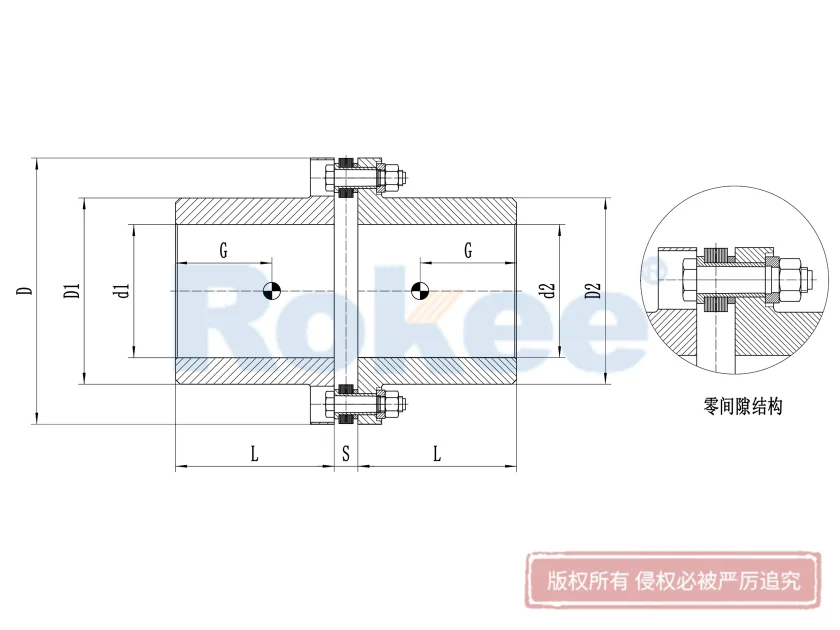

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

Rokee's RL series metal shim pack couplings are independently developed on the basis of high-quality products from Europe and Japan. Plate coupling has smaller volume, larger torque of the same type, more reasonable proportioning size, large compensation range, light weight and small moment of inertia. Special elastic gasket design is adopted in the hole connection part of bolt and diaphragm group, which greatly reduces the stress concentration in the hole edge part, eliminates the tear loss of diaphragm, and extends the service life. With modular design, the coupling assembly is simple and its maintenance and replacement are quick. The performance far exceeds the national standard JM series membrane disc couplings, which are widely used in fan systems, steam turbine units and other important industrial fields.

ROD Series Steel Laminae Couplings

-

RLM Small Single Diaphragm Coupling

RLM Small Single Diaphragm Coupling -

RLMD Small Double Diaphragm Coupling

RLMD Small Double Diaphragm Coupling -

RLA Standard Single Diaphragm Coupling

RLA Standard Single Diaphragm Coupling -

RLAD Standard Double Diaphragm Coupling

RLAD Standard Double Diaphragm Coupling -

RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling

RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling -

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling -

RLAF Large and Small Shaft Mounted Diaphragm Coupling

RLAF Large and Small Shaft Mounted Diaphragm Coupling -

RLAT Super Long Wheelbase Diaphragm Coupling

RLAT Super Long Wheelbase Diaphragm Coupling -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

RLQA No Flange Quick Installation Metal Diaphragm Coupling -

RLQF Flange Type Quick Installation Diaphragm Coupling

RLQF Flange Type Quick Installation Diaphragm Coupling -

RLQU Improved Flange Quick Installation Diaphragm Coupling

RLQU Improved Flange Quick Installation Diaphragm Coupling -

RLHD High Speed Diaphragm Coupling

RLHD High Speed Diaphragm Coupling