The curved-tooth gear coupling is a specially designed advanced gear type coupling. Its outer teeth are made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

China National Toothed Couplings

-

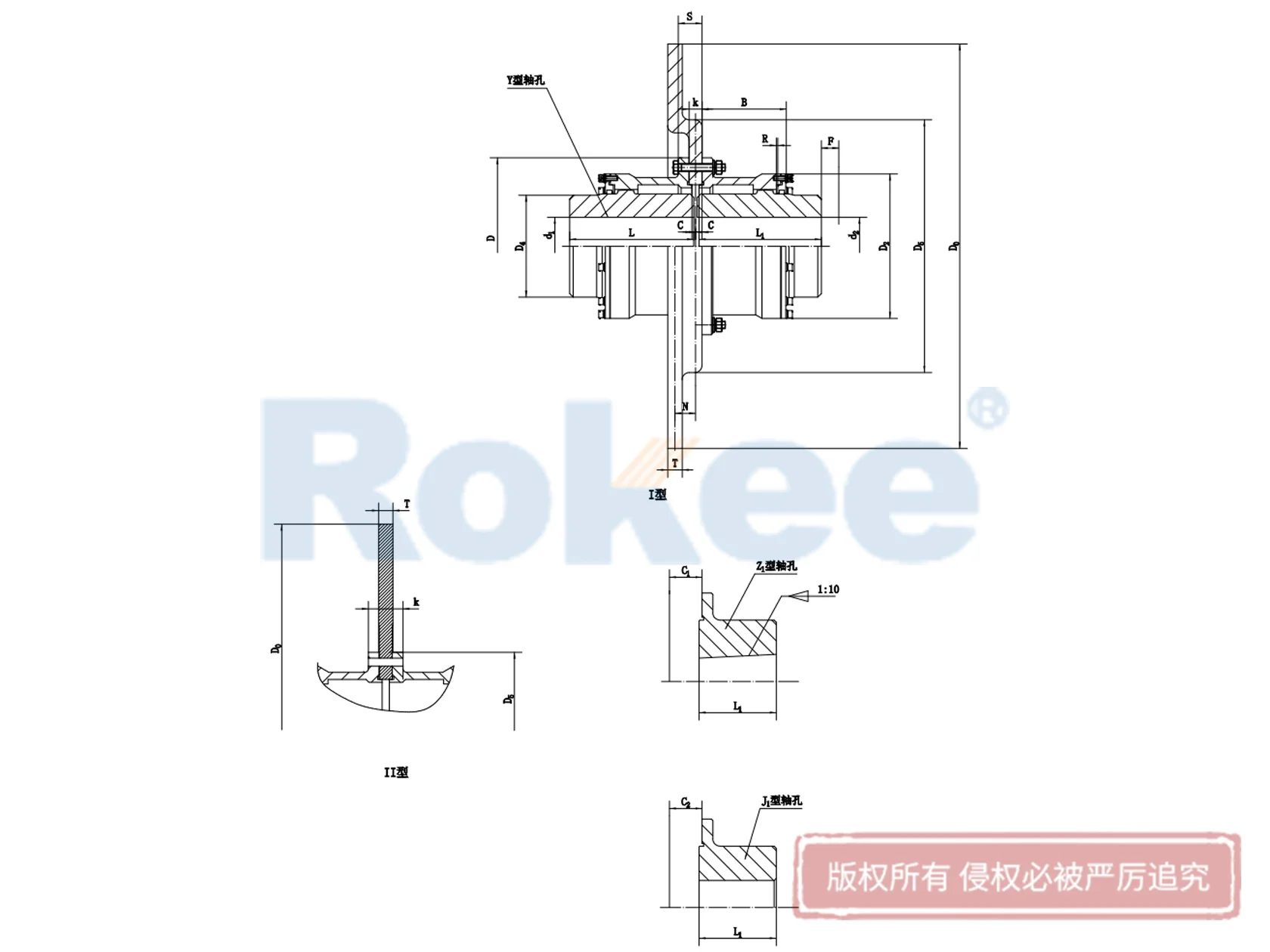

GICL Curved-tooth Gear Coupling

GICL Curved-tooth Gear Coupling -

GICLZ Curved-tooth Gear Coupling

GICLZ Curved-tooth Gear Coupling -

GIICL Curved-tooth Gear Coupling

GIICL Curved-tooth Gear Coupling -

GIICLZ Curved-tooth Gear Coupling

GIICLZ Curved-tooth Gear Coupling -

GCLD Curved-tooth Gear Coupling

GCLD Curved-tooth Gear Coupling -

NGCL Curved-tooth Gear Coupling With Brake Wheel

NGCL Curved-tooth Gear Coupling With Brake Wheel -

NGCLZ Curved-tooth Gear Coupling With Brake Wheel

NGCLZ Curved-tooth Gear Coupling With Brake Wheel -

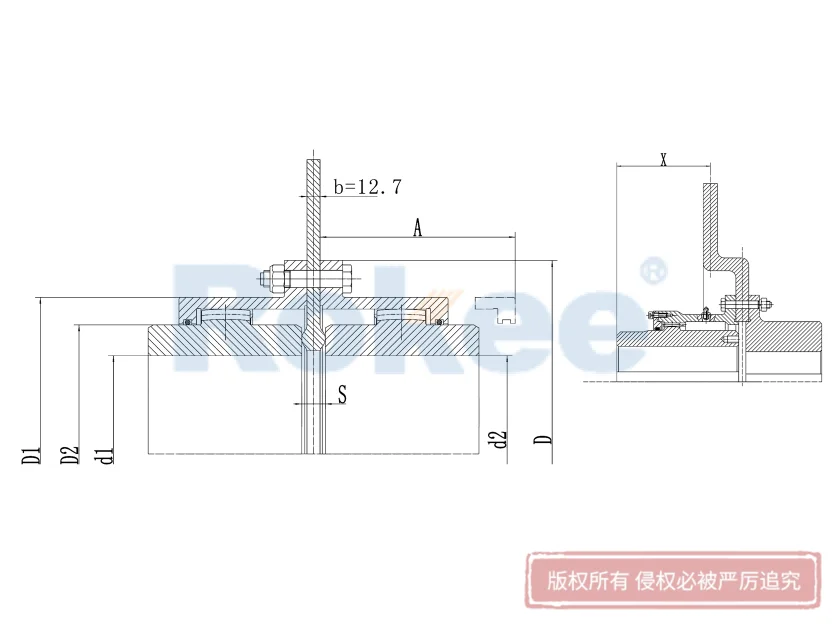

WG Curved-tooth Gear Coupling

WG Curved-tooth Gear Coupling -

WGZ Curved-tooth Gear Coupling With Brake Wheel

WGZ Curved-tooth Gear Coupling With Brake Wheel -

WGP Curved-tooth Gear Coupling With Brake Disc

WGP Curved-tooth Gear Coupling With Brake Disc -

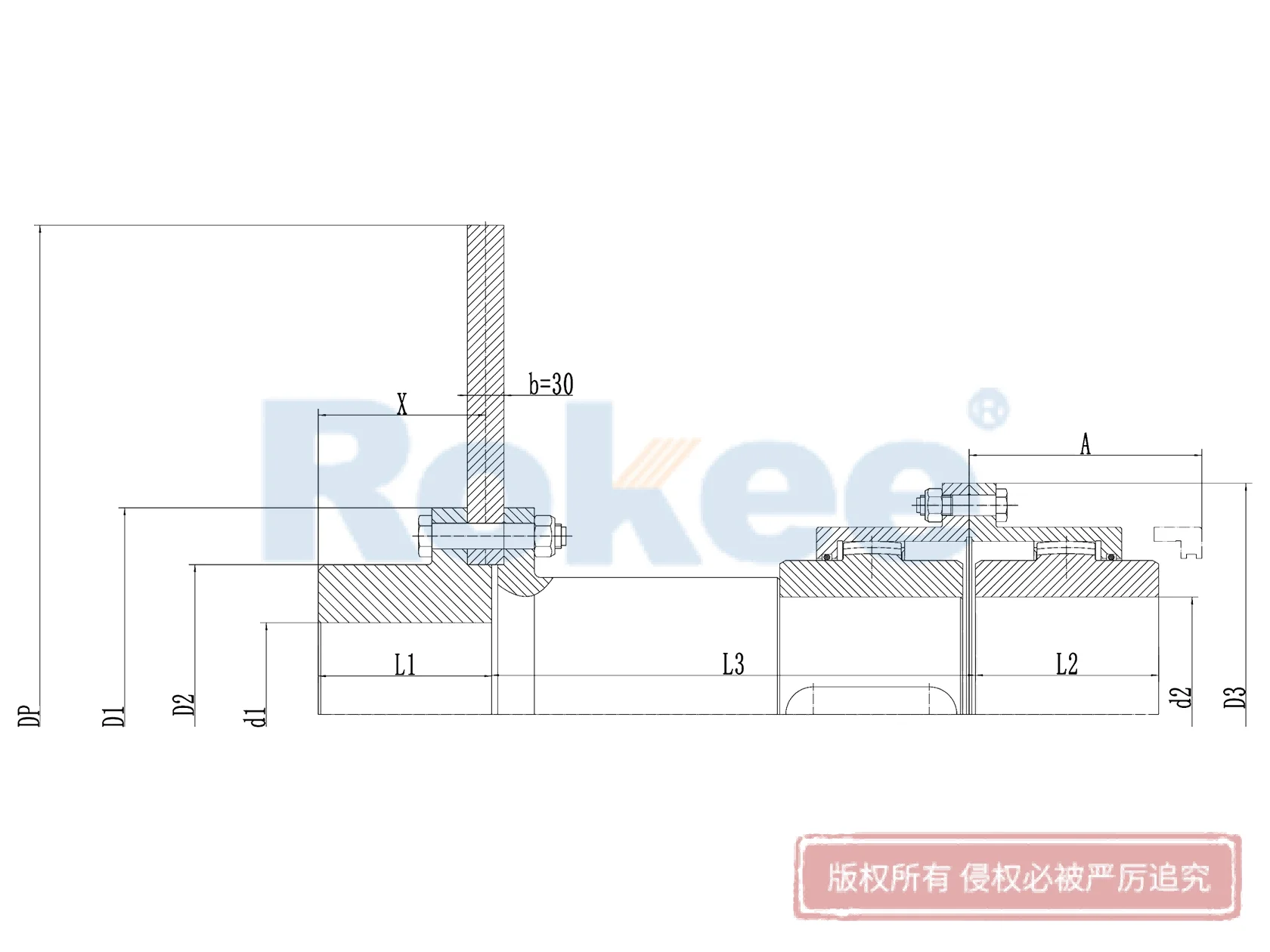

WGT Curved-tooth Gear Coupling With Indirect Tube

WGT Curved-tooth Gear Coupling With Indirect Tube -

WGC Curved-tooth Gear Coupling

WGC Curved-tooth Gear Coupling -

WGJ Curved-tooth Gear Coupling With Intermediate Shaft

WGJ Curved-tooth Gear Coupling With Intermediate Shaft

ROD crown gear coupling is one of the transmission products with core technology independently developed by Rokee and has established and reported corporate technical standards in the country. By combining with the standard coupling technology of advanced countries such as Japan and Germany, we optimized many detailed dimensions, and adopted the toothed design with a large pressure angle and short shaft design for the shaft hole, which reduces the length-diameter ratio, and has a more compact structure and excellent speed performance. The bolts of similar types are standardized and the parts are universal. Compared with the national standard couplings, our standard couplings can transfer more torque, with greatly reduced mass and small moment of inertia. Brake drum gear coupling meets the European explosion-proof requirements and the comprehensive performance is greatly advanced. We highly recommend you to choose our products for better transmission performance.

ROD Series Curved Tooth Couplings

-

RODA Curved-tooth Gear Coupling

RODA Curved-tooth Gear Coupling -

RODT Indirect Tube Curved-tooth Gear Coupling

RODT Indirect Tube Curved-tooth Gear Coupling -

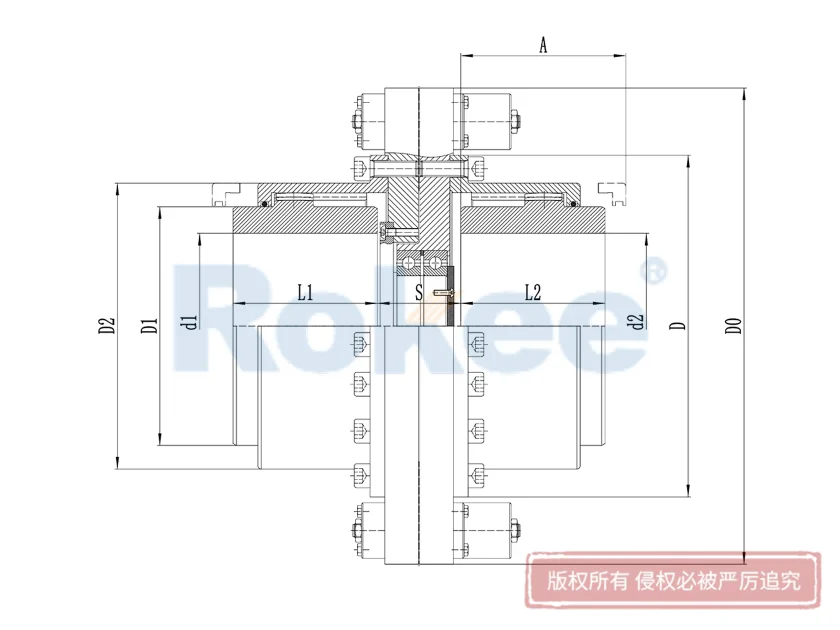

RODX Intermediate Shaft Curved-tooth Gear Coupling

RODX Intermediate Shaft Curved-tooth Gear Coupling -

RODP Brake Disc Curved-tooth Gear Coupling

RODP Brake Disc Curved-tooth Gear Coupling -

RODF Split Brake Disc Curved-tooth Gear Coupling

RODF Split Brake Disc Curved-tooth Gear Coupling -

RODW Brake Wheel Curved-tooth Gear Coupling

RODW Brake Wheel Curved-tooth Gear Coupling -

RODU Brake Wheel Curved-tooth Gear Coupling

RODU Brake Wheel Curved-tooth Gear Coupling -

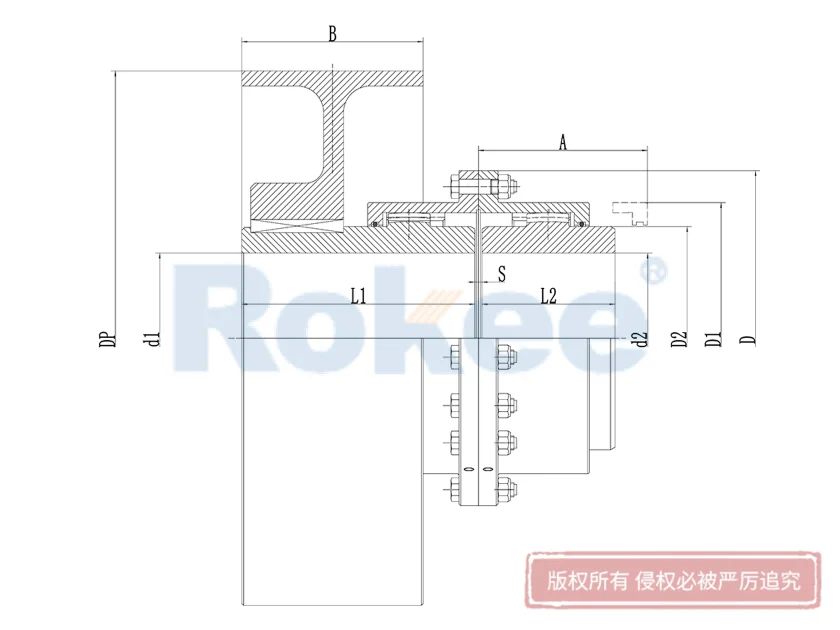

RODV Vertical Installation Curved-tooth Gear Coupling

RODV Vertical Installation Curved-tooth Gear Coupling -

RODM Torsion Protection Curved-tooth Gear Coupling

RODM Torsion Protection Curved-tooth Gear Coupling