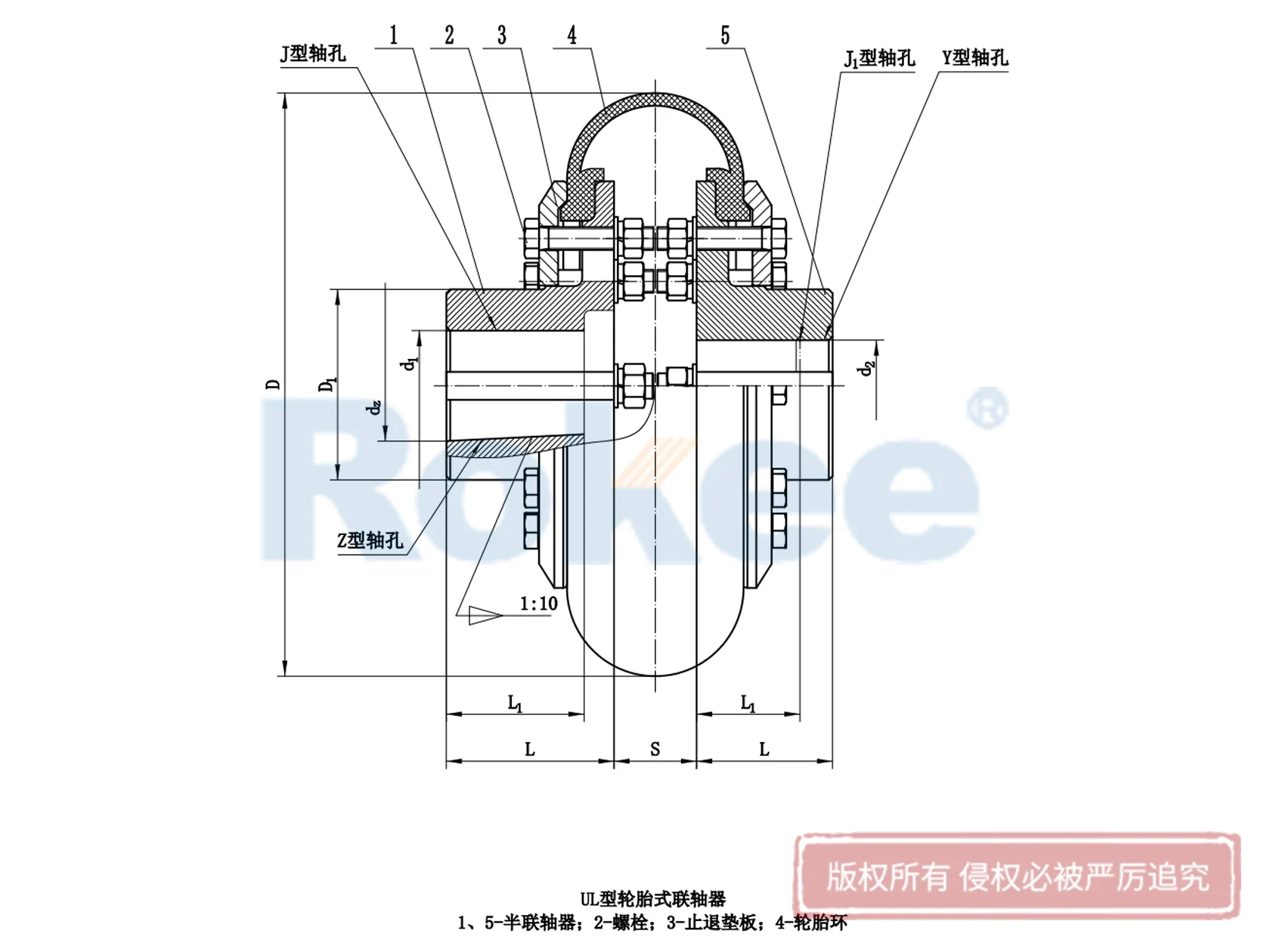

When selecting, it is necessary to consider factors such as the transmission torque, allowable speed, shaft hole diameter, and length of the tire coupling to ensure that it meets the usage requirements. Tire couplings are widely used in various mechanical equipment, especially suitable for working conditions such as humidity, dust, impact, vibration, variable forward and reverse rotation, and frequent starting.

When installing Rubber Tire Couplings, measures should be taken to ensure that the stress direction in the tire is opposite to the stress direction generated during operation, in order to offset some additional axial forces and improve the working conditions of the coupling and two bearings. At the same time, it is necessary to regularly check the wear of tire couplings and replace damaged components in a timely manner to ensure their normal operation.

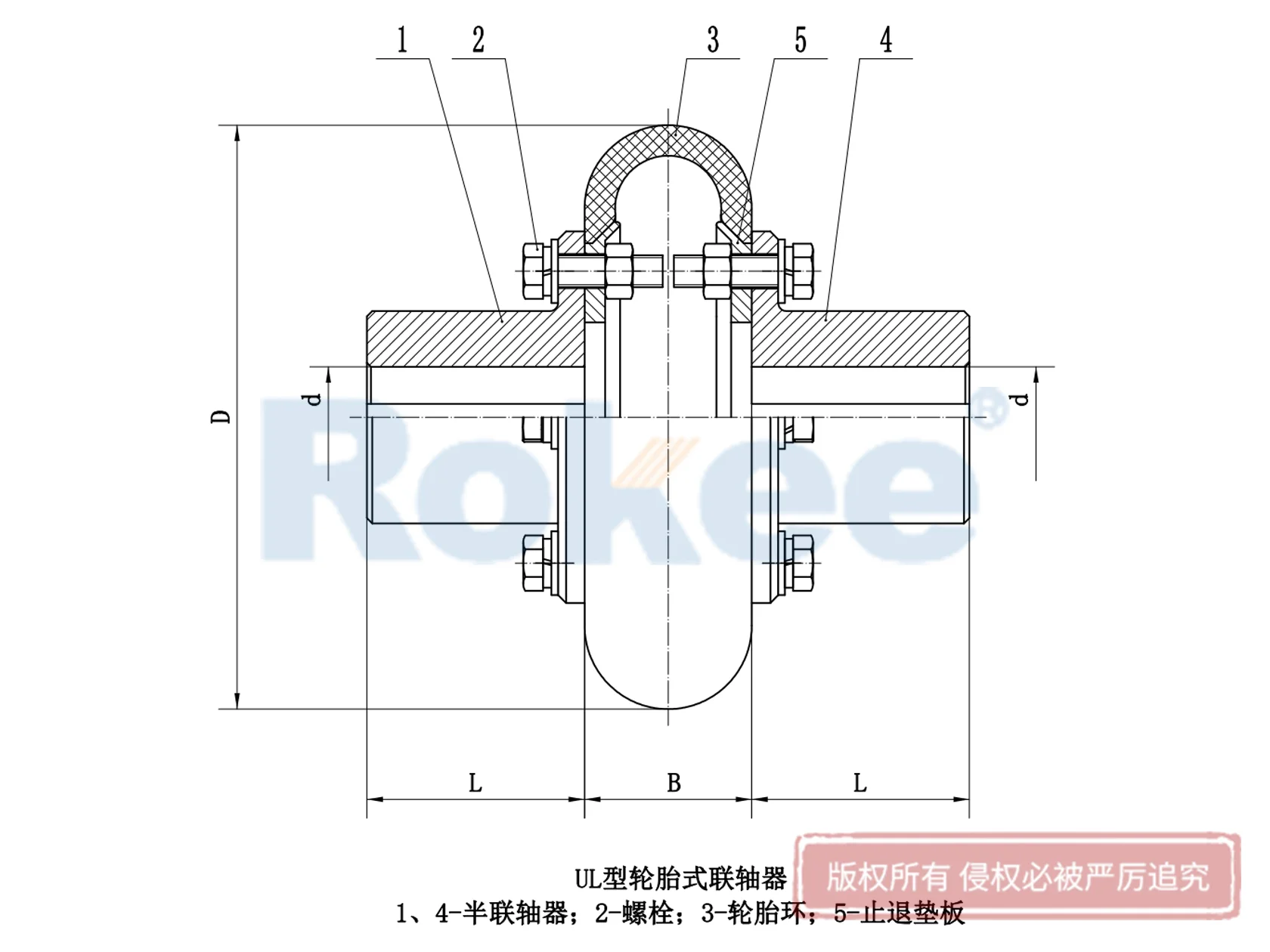

Flexible Tyre Couplings, as an important mechanical transmission component, play a crucial role in various types of mechanical equipment. Understanding its structure, working principle, selection and application, as well as installation and maintenance knowledge, can help to better use and maintain tire couplings, ensuring their long-term stable operation.