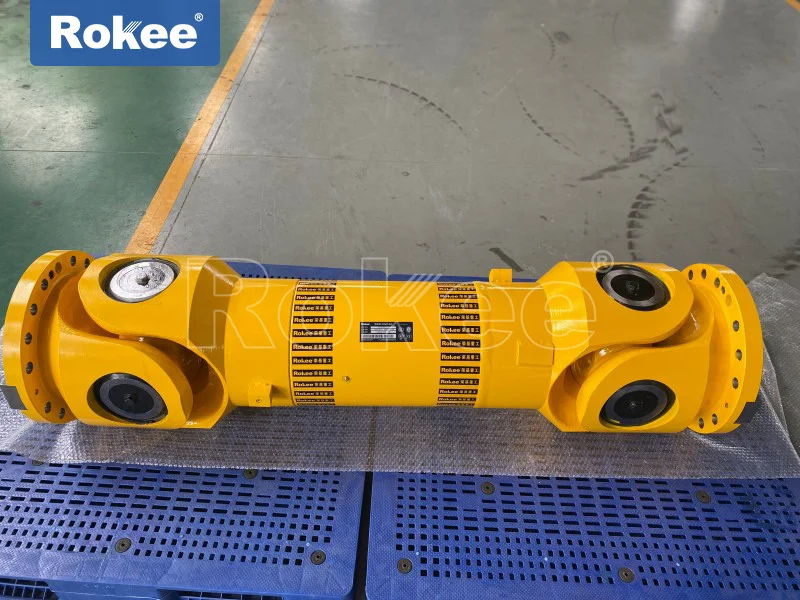

SWC Universal Coupling

SWC universal coupling as a key component in the field of mechanical transmission, plays an irreplaceable role in modern industrial equipment. This cross axis universal coupling, which adopts an integral fork head without bolt connection structure, has become the preferred transmission solution in industries such as metallurgy, lifting, and engineering transportation due to its good reliability and efficient transmission performance.

The SWC cross axis universal coupling is a mechanical transmission device that adopts an integral fork head bolted connection structure, representing an important advancement in universal coupling technology. Compared with traditional bolt clamping design couplings, SWC type couplings significantly improve structural strength and operational reliability by eliminating the weak link of bolt connection. This innovative design solves the long-standing problem of equipment failure caused by loose or broken bolts in the industry, increasing the service life of the coupling by 30% -50% compared to other types, and demonstrating good durability in heavy-duty industrial applications.

The application range of SWC universal coupling is extremely wide, covering almost all heavy industry fields. In metallurgical machinery, it is used for key equipment such as rolling mills and cooling beds; In mining machinery, it provides reliable power transmission for the conveying system and crusher; SWC universal couplings also perform well in the fields of petroleum, shipbuilding, and engineering transportation. In addition, it is widely used in industries such as coal, rubber, and paper machinery, becoming the core component for transmitting torque in mechanical shaft systems. This broad applicability stems from its innovative design concept and excellent engineering performance, enabling it to adapt to various complex working conditions and environmental conditions.

The SWC universal coupling is mainly composed of key components such as flange fork, sleeve fork, cross bearing, transmission spline, and spline sleeve. The bearing fixing mechanism adopts a bolt free design, which avoids accidental shutdown caused by bolt failure. The spline connection device adopts a double-layer structure, effectively preventing the problem of key tooth wear. In terms of material selection, the product blank is usually made of 35CrMo alloy steel and undergoes quenching and tempering treatment, while the spline shaft is subjected to high-frequency quenching processing to ensure overall strength and wear resistance. This carefully designed structural combination enables the SWC universal coupling to adapt to complex working conditions with axial, radial, and angular displacements, meeting the demanding requirements of heavy-duty equipment shaft transmission.

BH type (standard expansion welding type) and BF type (standard expansion flange type) are two common basic models in the SWC series. BH type is connected by welding, which has the advantages of simple structure and light weight; The BF type adopts flange connection, which is easy to disassemble and maintain. Both models have standard expansion and contraction capabilities, which can compensate for axial displacement within a certain range. They are suitable for conventional application scenarios such as rolling mills in metallurgical machinery and conveyor systems in mining machinery. In practical engineering, the choice between welded or flange type mainly considers factors such as installation conditions, maintenance frequency, and the need for frequent disassembly.

For situations that require a larger range of expansion and contraction adjustment, SWC couplings offer two specially designed options: DH type (short expansion welding type) and CH type (long expansion welding type). The CH type long telescopic welded cross axis universal coupling is particularly suitable for two shaft connections with large axial movement, and can handle continuous rotation at equal angular velocity without being on the same axis or with large axis angles. Widely used in large-scale equipment in metallurgy, lifting, engineering transportation, mining, petroleum and other industries, especially in situations where there are significant installation errors or significant displacement during operation.

In space limited applications, the WH type (non expansion welded type), WF type (non expansion flange type), and WD type (non expansion short type) three non expansion models demonstrate unique advantages. The SWC-WD type non expandable short cross axis universal coupling has a particularly compact structure and is suitable for applications with limited installation space but still requiring angle compensation, such as the main and auxiliary transmission systems of rolling mills, as well as lifting, mining, engineering vehicles and other equipment. Although these non retractable models cannot compensate for axial displacement, they perform excellently in terms of angle compensation capability, with SWC type axis bending angles up to 15 ° -25 °. Practical application has proven that using non expandable models in situations where axial compensation is not required can simplify the structure, reduce costs, and ensure transmission efficiency and reliability.

The industry application distribution of SWC universal coupling is extremely wide, covering almost all heavy industry fields. In the metallurgical industry, it is used in key processes such as rolling mill transmission and cold bed conveying; In the mining industry, it provides reliable power transmission for crushers, ball mills, and conveying equipment; In terms of engineering transportation, SWC universal couplings are the core components of various heavy-duty vehicle transmission systems. In addition, it is widely used in various industries such as oil drilling and production equipment, ship propulsion systems, coal machinery, rubber processing machinery, paper machinery, etc. This wide applicability stems from the diverse model design and excellent performance of SWC series couplings, which can meet the special needs of different industries.

-

Classification Of Universal Joint Couplings

-

Model Of Cross Axis Universal Shaft Coupling

-

Working Principle Of Cardan Shaft Coupling

-

Structure Of Universal Shaft Coupling

-

Short Telescopic Universal Joint Coupling

-

Heavy Duty Universal Joint Couplings

-

Function Of Universal Joint Coupling

-

Types Of Universal Joint Couplings