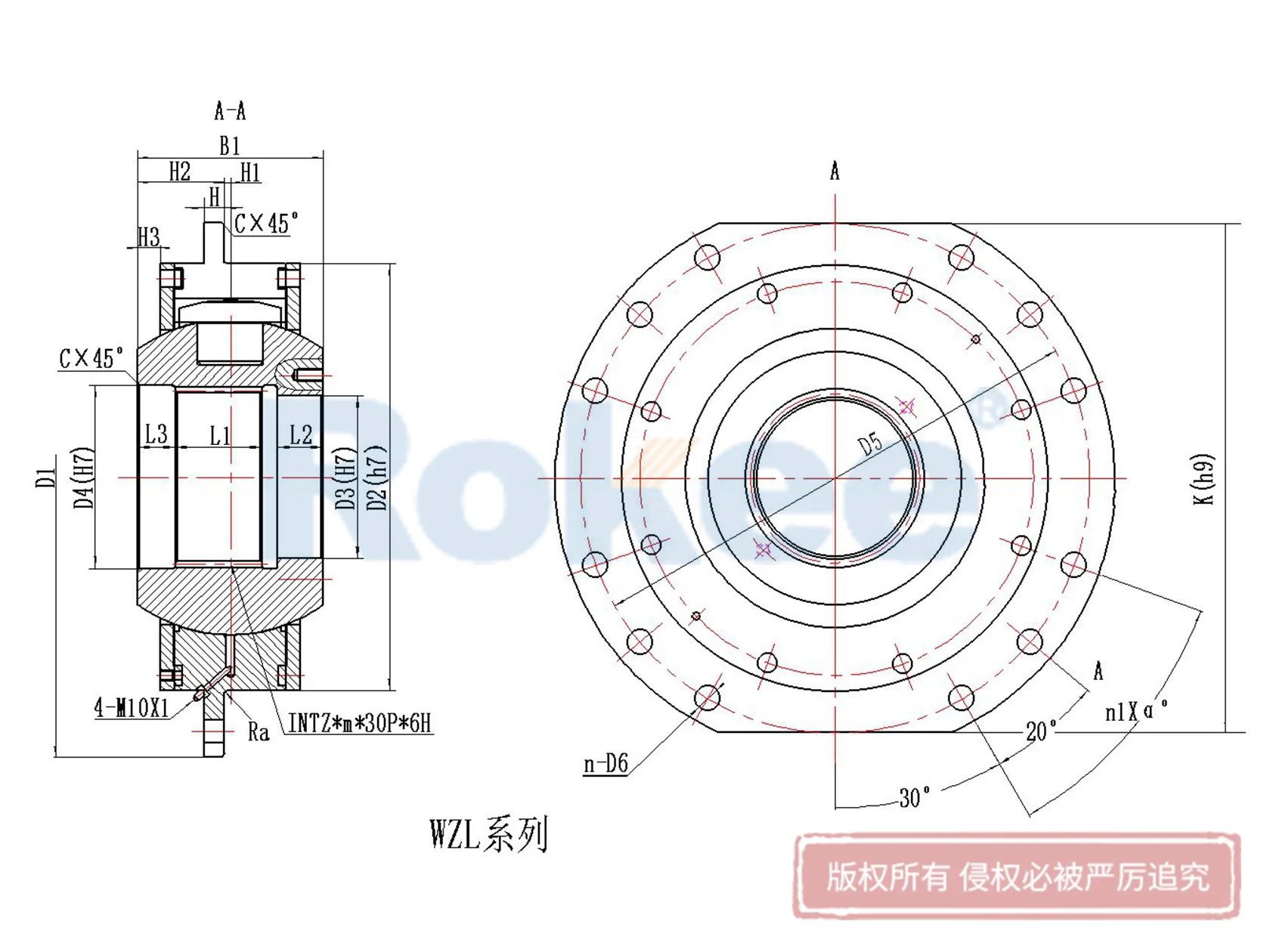

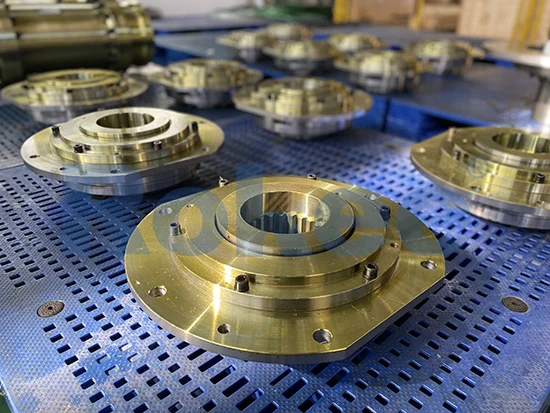

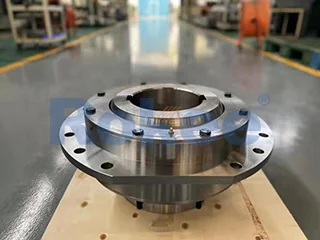

There are various types of barrel couplings, such as WJA cylindrical shaft hole connected spherical roller couplings, WZL drum couplings, DC toothed drum couplings, etc. When selecting, comprehensive consideration should be given to the specific requirements, working environment, and performance parameters of the lifting equipment to ensure that the selected coupling can meet the operational requirements of the equipment.

As an important component in lifting equipment, the barrel coupling has the characteristics of compact structure, stable and reliable operation, and good positioning performance. During installation and maintenance, it is necessary to strictly follow the relevant requirements to ensure its normal operation and extend its service life.